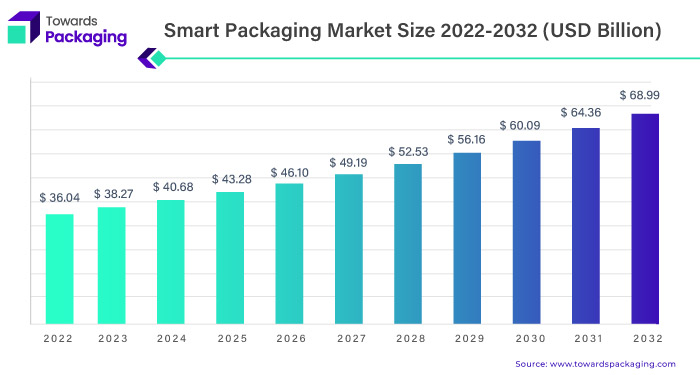

The global smart packaging market size has emerged as a key player, with an estimated size of USD 36.04 billion in 2022 to hit USD 68.99 billion by 2032, registering CAGR of 6.8% from 2023 to 2032.

Understanding Smart Packaging Market

What Sets Smart Packaging Apart?

Smart packaging market goes beyond traditional methods by incorporating innovative technologies to enhance product functionality, safety, and consumer engagement. From RFID tags to temperature sensors, smart packaging market is equipped with a myriad of features that enable real-time tracking, monitoring, and communication.

Driving Forces Behind the Growth

The surge in the global smart packaging market can be attributed to several factors, including:

1. Technological Advancements

The relentless march of technology has paved the way for groundbreaking innovations in smart packaging market. Integration with IoT (Internet of Things) devices has enabled seamless communication, ensuring a more connected and intelligent supply chain.

2. Consumer Demand for Transparency

Modern consumers are more discerning than ever, demanding transparency and information about the products they purchase. Smart packaging market caters to this demand by providing real-time data on product origin, expiration dates, and storage conditions.

3. Environmental Sustainability

With environmental concerns taking center stage, smart packaging market has evolved to address sustainability issues. Features like biodegradable materials and reduced packaging waste contribute to a greener, more eco-friendly approach.

Market Projections and Future Trends

Projections for 2032

The anticipated market size of USD 68.99 billion by 2032 underscores the immense potential of smart packaging market. As industries continue to adopt and integrate these technologies, the market is poised for exponential growth.

Future Trends Shaping the Landscape

1. Personalized Consumer Experiences

Smart packaging market enables brands to deliver personalized experiences to consumers. From interactive labels to augmented reality features, companies can create unique, memorable engagements that foster brand loyalty.

2. Integration with E-Commerce

In an era dominated by online shopping, smart packaging market plays a crucial role in enhancing the e-commerce experience. Features like package tracking, tamper-evident seals, and interactive QR codes provide added value for consumers and businesses alike.

3. Healthcare Revolution

The healthcare sector is embracing smart packaging market to ensure the integrity of pharmaceuticals, monitor patient adherence, and streamline supply chain logistics. This trend is anticipated to revolutionize the healthcare packaging landscape.

Unveiling the World of Smart Packaging Market

-

Strategic Integration of Advanced Technologies

- RFID tags, sensors, and QR codes enhance packaging intelligence.

- Empowers manufacturers for active monitoring and traceability across the supply chain.

-

Enhanced Business Outcomes

- Proactive thinking, seamless communication, and interactive capabilities.

- Engages discerning consumers through innovative packaging solutions.

Advantages of Smart Packaging Market Adoption

Elevating Customer Experience

-

Additional Functionalities for Convenience

- Optimize convenience, safety, and usability.

- Embedded sensors enable real-time monitoring of vital parameters.

-

Real-time Monitoring of Parameters

- Humidity, temperature, and integrity.

- Ensures optimal product quality throughout the entire value chain.

Bolstering Product Safety and Security

-

Robust Product Tracking and Authentication

- Utilization of RFID tags and QR codes.

- Safeguards consumer well-being and protects brand reputation.

-

Anti-counterfeiting Measures

- Ensures trust within the marketplace.

Supporting Sustainability Initiatives

-

Optimizing Inventory Management

- Streamlining supply chain operations with RFID tags.

- Minimizing excess inventory and mitigating environmental impact.

-

Reducing Waste and Facilitating Recycling

- QR codes provide consumers information on proper disposal methods.

- Encourages responsible post-consumption practices.

Smart Packaging Market: A Catalyst for Excellence

-

Superior Product Quality

- Integration of sensing, evaluation, identification, tracking, and reporting.

- Consistent adherence to rigorous quality standards.

-

Optimizing Supply Chain Efficiency

- Seamless and enriched customer experience.

Growth and Challenges in Smart Packaging Market

-

Robust Growth

- Adaptability to the ever-changing market landscape.

- Consumer expectations rise with continuous smartphone advancements.

-

Investments in Smart Packaging Market

- Significant resources from major packaging companies.

- Ongoing growth tempered by increasingly stringent regulatory environments.

-

Challenges and Opportunities

- Evolving social demographics pose challenges.

- Vast opportunities available with receptiveness and adaptability to change.

Evolution of Food Packaging: From Traditional to Smart

-

Urbanization and Demand for Convenience

- Two-thirds of the global population in urban areas by 2025.

- Driving demand for convenient, high-quality food products.

-

Challenges in India’s Food Processing Industry

- 20% of produced goods wasted due to inadequate processing and packaging.

- Immense potential for growth, attracting significant investments.

-

Steady Growth in Indian Packaging Industry

- 12% annual growth rate.

- Encompassing 22,000 companies from raw material to machinery suppliers.

-

Post-Harvest Storage Conditions

- Influence shelf life of food products.

- Optimal storage conditions vary based on the type of food product.

-

Core Functions of Food Packaging

- Containment, protection, convenience, and communication.

- Effective solutions strive to deliver optimal condition to end-users.

Smart Packaging in Food Industry: Innovative Solutions

-

Communication Capabilities for Decision-making

- Capitalizing on packaging’s communication capabilities.

- Facilitating decision-making processes and enhancing food safety and quality.

-

Intelligent Packaging Features

- Sensing, detecting, tracing, recording, and communicating.

- Facilitating prolonged shelf life, improved product quality, and enhanced safety measures.

-

Real-world Example: Coca-Cola’s Dynamic QR Codes

- Enhanced consumer engagement through strategic QR code implementation.

- Offers unique experiences to customers, fostering brand interaction.

Driving Efficiency and Connectivity: Harnessing Intelligent Packaging within the Smart Packaging Market

Intelligent packaging encompasses a wide range of technologies that collectively serve specific functions and provide information to consumers regarding food products. There are three main types of intelligent packaging, each with its primary function. These technologies differ not only in their physical and chemical compositions but also in how they communicate detected changes and the quantity and nature of data they can transmit. Additionally, they vary in their mechanisms for capturing and disseminating data.

Instance, On May 20, 2022, Sealed Air, a reputable member of AIPIA (Active & Intelligent Packaging Industry Association), launched its new digital packaging brand, Prismiq. Prismiq offers various solutions, including design services, digital printing, and intelligent packaging.

This comprehensive portfolio of offerings is designed to cater to the diverse needs of businesses in the packaging industry, empowering them to harness cutting-edge technologies and elevate their packaging capabilities. By leveraging Prismiq’s innovative solutions, companies can enhance their packaging designs, incorporate digital printing techniques, and take advantage of intelligent packaging technologies for added functionality and value.

- Interactive packaging: This type of packaging serves as a data carrier, allowing for the storage and retrieval of information related to the storage, distribution, and traceability of food products. Interactive packaging, also known as automatic identification devices, facilitates the efficient flow of information within the food supply chain.

The main objectives of interactive packaging include ensuring traceability, preventing theft, and providing counterfeit protection. Standard technologies in this category include barcode labels (such as 2D codes) and RFID tags, which enhance convenience and enable data transmission. Sensor-enabled RFID tags can also monitor storage conditions (e.g., temperature, humidity, and light) and food quality throughout the supply chain.

- Sensors: Sensors play a crucial role in packaging by gathering information about the package and its contents. They can detect changes in the environment and assess the condition or operational history of the packaged material. Sensors are designed to monitor specific functionalities such as pH levels, time, temperature, hydrogen sulphide, or carbon dioxide presence.

In food packaging, sensors are used to ensure the quality and safety of food products, with the sensors integrated into the packaging materials. Sensors consist of a receptor and a transducer, providing a continuous signal to measure chemical or physical properties.

- Indicators: Unlike sensors, indicators do not provide quantitative information or store measurement data and time. Instead, they offer visual or qualitative (sometimes semi-quantitative) information about the packaged food through colour changes. Indicators primarily convey information through colour intensity variations or irreversible diffusion.

They are commonly used to indicate temperature changes, gases and volatiles, pH changes, and microbiological contamination. Indicators serve as visual cues regarding the condition or environment of the packaged food.

Role Evolution of Packaging

- Consumer Demands

- Informed and discerning consumers seek cost-effective, visually appealing, and authentic packaging.

- Transition from conventional to smart packaging to meet evolving demands.

Smart Packaging in Pharma: Innovations and Benefits

- Innovative Technologies in Smart Packaging

- Tracking, monitoring, and information dissemination.

- Enhanced product protection, improved safety measures, and increased consumer engagement.

- Bostik’s Smart Blister Packaging

- Introduction on 14 April 2021.

- Demonstrates commitment to evolving pharmaceutical needs.

- Incorporates cutting-edge technology for safety, convenience, and functionality.

- Benefits of Smart Packaging Adoption

- Addresses consumer concerns about product authenticity.

- Provides crucial information about dosage instructions and medication usage.

- Facilitates improved supply chain management and enhances patient compliance.

Diverse Smart Packaging Solutions in Pharma

- Paper-based RFID tags

- Environmentally friendly alternative to plastic.

- Efficient tracking and identification of medication throughout the supply chain.

- Unique bag-type combination products

- Simplify reconstitution of dry powder medications.

- Designed for convenient patient use.

- Intelligent ink

- Changes color to indicate proper storage conditions.

- Ensures medication effectiveness and safety.

- Self-dose patient-controlled injector

- Minimizes pain and discomfort for patients.

- Enables self-administration of regular medication doses.

- Smart closures with NFC or Electronic Dose Pack

- Records date and time of each dose taken.

- Transmits data for analysis, aiding medication adherence.

- 2D barcode for Vaccine Vial Monitors

- Captures lot numbers and expiration dates.

- Scannable for product authenticity and safety details.

- Intelligent inhalers

- Utilize breath actuation for proper device usage.

- Connect to smartphones for reminders and feedback.

Real-Time Tracking and Information Access

- Real-Time Tracking of Shipments

- Valuable information for invoicing, reordering, and improving product handling processes.

- Comprehensive Information Access

- Storage instructions, reconstitution processes, administration guidelines, and proper disposal details.

- Promotes safe and effective product usage.

Future Trends: Sensor-Enabled Packaging

- Significant Potential of Sensor-Enabled Packaging

- Real-time monitoring of stock levels.

- Enables timely replenishment and efficient production planning.

- Data-driven approach adjusts production and supply strategies based on actual stock availability.

QR Codes and Smart Packaging: Enhancing Traceability and Supply Chain Efficiency

Barcodes have long been recognized as reliable and efficient smart packaging technology. However, traditional one-dimensional barcodes have limitations regarding how much information they can hold. In contrast, two-dimensional barcodes, also known as smart packaging codes, offer significantly greater data storage capacity by utilizing a combination of dots and empty spaces within a compact area.

QR codes are a prominent example of two-dimensional barcodes and have gained widespread adoption due to their compatibility with smartphones equipped with cameras and internet connectivity. By scanning QR codes with their smartphones, consumers can access a wide range of content, including product information or any other content that manufacturers wish to present. Manufacturers and retailers leverage QR codes for detailed product traceability and efficient supply chain management.

In addition to QR codes, other smart packaging codes encompass technologies such as smart labels, data matrix codes, RFID, and NFC chips. These solutions effectively transform the packaging into data carriers and digital tools.

- For instance, startups utilize QR data matrix codes on their products to establish unique digital identities, enabling enhanced product tracking and authentication.

Integrating two-dimensional barcodes and smart packaging codes empowers manufacturers and retailers to leverage packaging for information dissemination, product traceability, and supply chain optimization. These technologies offer versatile possibilities and contribute to digitizing and advancing packaging capabilities in diverse industry sectors.

NFC (Near Field Communication) is a cutting-edge wireless technology that facilitates seamless communication between devices, predominantly smartphones or NFC readers, and NFC-enabled tags or labels. When integrated into packaging, these NFC tags offer valuable functionalities such as authentication, product information dissemination, or interactive content engagement with a simple tap or scan by compatible devices.

On the other hand, data matrix codes represent sophisticated two-dimensional barcodes capable of efficiently storing substantial volumes of data. These codes find utility in packaging by encoding essential information like serial numbers, batch numbers, or expiration dates. Employing barcode scanners or smartphone apps, these data matrix codes can be effortlessly scanned to support diverse applications, including inventory management, traceability, and quality control.

Leveraging smart packaging codes goes a long way in enhancing package traceability while streamlining product authentication through the utilization of consumer scan data. This proactive approach plays a vital role in combatting counterfeiting practices. Moreover, smart packaging captivates consumers, and implementing smart codes equips businesses with highly pertinent data points, subsequently amplifying brand awareness and fostering customer retention.

Smart Packaging Market Dynamics: Regional Factors Shaping Market Evolution

Based on the research conducted during the covered period, the smart packaging market is projected to experience the most significant growth rate in the Asia-Pacific region.

Smart packaging represents the latest breakthrough in the Korean packaging industry, offering technological advancements that enhance consumer interaction and communication with products. This technology enables the creation of user-friendly and convenient products and packages. Some packages are equipped with technology that provides users with product information, such as usage instructions and remaining shelf life until the expiration date.

The smart design aligns with the growing emphasis on sustainability, considering the environmental impact and delivering more convenient and user-friendly products through innovative packaging designs. These smart designs empower consumers of all ages to easily use products. For example, a new medical pill bottle features an “easy cap” with a device inside that cuts the aluminium foil when the cap is twisted and opened. This not only ensures the safety and integrity of the product but also enhances customer convenience.

Innovative packaging designs incorporating smart technology can have unexpected economic effects as various technological fields converge within a single package. Moreover, new packaging technologies offer benefits to companies as well. Through interactive packaging, companies can trace the journey of their products from store shelves to consumers, facilitating better supply chain management.

The Korean packaging industry, valued at $30.3 billion annually, surpasses the size of the entire design industry. Its economic impact generates 159,351 jobs, contributing to an impressive annual growth rate of 6.8%, which is higher than the current average growth rate of the economy, according to the Korea Packaging Industry. With increased product exports, the Korean packaging industry will produce more packages that effectively protect products during transportation, ensuring their quality in varying weather conditions until they reach customers.

Smart Packaging Market: Comparative Analysis of Leading Players and Competitive Strategies

The smart packaging market is characterized by intense competition and a diverse range of players offering innovative solutions. Key players in the market include industry leaders such as Amcor PLC, known for its comprehensive portfolio of intelligent packaging solutions. Avery Dennison Corporation, a prominent provider of labelling and packaging materials, excels in integrating technologies like RFID and NFC to enable product tracking and authentication.

BASF SE stands out with its advanced materials and sensor technologies that enhance the functionality of smart packaging market. Smartrac Technology Group specializes in RFID and NFC technology solutions, catering to global clients with product authentication and supply chain optimization offerings. Stora Enso Oyj is recognized for its renewable packaging solutions, including intelligent paper packaging and connected platforms.

Thinfilm Electronics ASA excels in printed electronics and NFC-based smart packaging solutions. 3M Company offers diverse smart packaging market solutions, including intelligent labels and adhesives. Sealed Air Corporation stands out with its comprehensive portfolio of smart packaging solutions, particularly for food, healthcare, and industrial applications. With continuous advancements and new entrants in the market, the smart packaging landscape is highly dynamic, fostering innovation and driving the industry forward.

Some major key players in the smart packaging market include: 3M, Avery Dennison Corporation, Ball Corporation, BASF SE, Crown International Paper, R.R. Donnelley & Sons Company, Stora Enso, Sysco Corporation, Zebra Technologies Corp. (Temptime Corporation).

Recent Development:

- June 23, 2023, During the AIPIA World Congress, notable advancements in smart packaging were showcased, including Wiliot’s groundbreaking battery-free IoT pixels utilizing RFID technology. These pixels have the unique capability of self-powering by harvesting ambient radio waves. This innovation marks a significant development in smart packaging market, enabling enhanced functionality and sustainability by eliminating the need for traditional power sources like batteries.

- Jun 20, 2022, Sealed Air’s Prismiq suite of digital technologies for printing, smart packaging market, and design revolutionizes the landscape of flexible packaging by enabling enhanced connectivity and integration.

Segments Covered in the Report:

By Type

- Active Packaging

- Oxygen Scavengers

- Moisture Scavengers

- Self-Venting Films

- Ethylene Scavengers &Emitters

- Microwave Susceptors

- Antibacterial Films

- Temperature Control Packaging

- Carbon Dioxide Scavengers/Emitters

- Ethanol Emitters

- Flavour/Odour Absorbers

- Antioxidants

- Intelligent Packaging

- Indicators

- Sensors

- Bio Sensors

- Gas Sensors

- Data Carriers

- Barcodes

- 2D Matrix Codes

- Quick Response Codes

- Augmented Matrix Codes

- RFID Tags

- Barcodes

- Modified Atmosphere Packaging

By Application

- Food & beverage

- Personal care

- Automotive

- Healthcare

- Others

By Material

- Solid

- Liquid

By Geography

- North America

- U.S.

- Canada

- Europe

- U.K.

- Germany

- France

- Asia-Pacific

- China

- India

- Japan

- South Korea

- Malaysia

- Philippines

- Latin America

- Brazil

- Rest of Latin America

- Middle East & Africa (MEA)