Table of Contents

ToggleGrowing Demand for Pressure-Sensitive Labels Market Expected to Hit $162.41 Billion by 2034

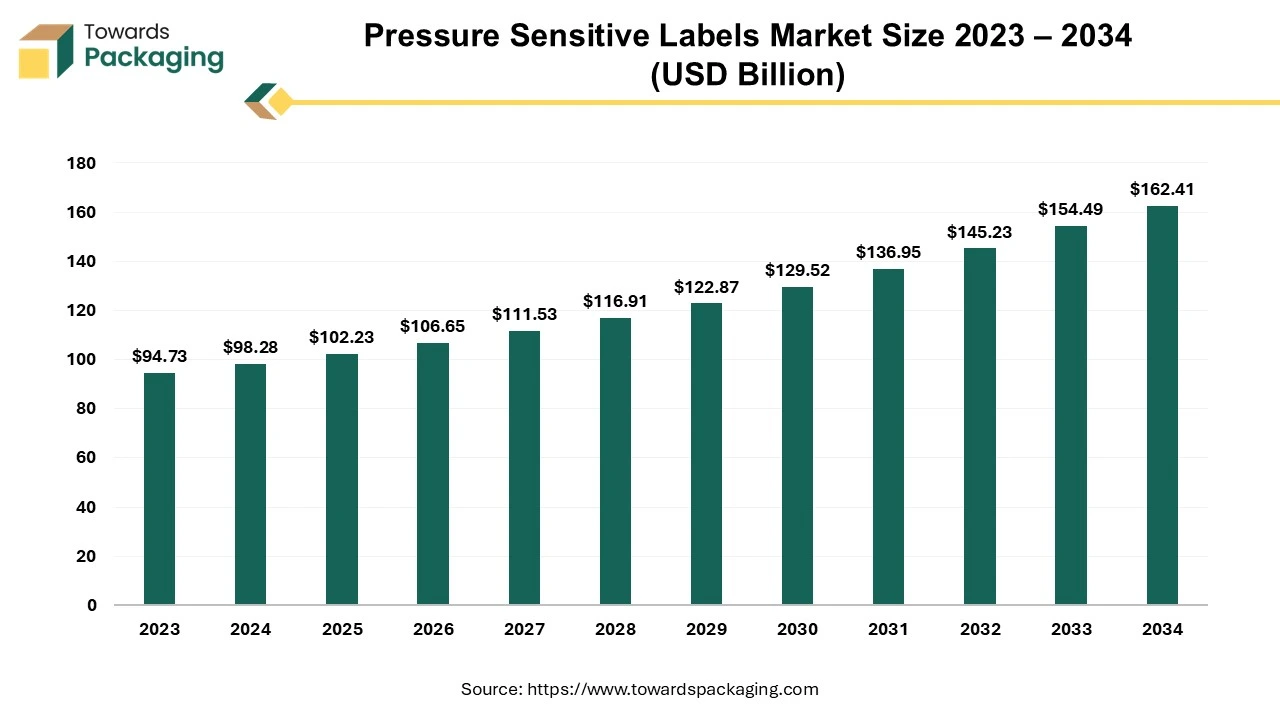

The global market for pressure-sensitive labels is projected to grow significantly, increasing from $94.73 billion in 2023 to an estimated $162.41 billion by 2034. This represents a compound annual growth rate (CAGR) of 5.15% during the forecast period from 2024 to 2034. The rising adoption of these labels across various industries is driving this robust growth.

Download Statistical Data: https://www.towardspackaging.com/download-statistics/5381

Key Trends and Insights in the Pressure-Sensitive Labels Market

The pressure-sensitive labels (PS labels) market is evolving with several exciting trends and innovations:

- Sustainability Takes Center Stage:

As consumers grow more environmentally conscious, companies are increasingly adopting sustainable packaging solutions. Many PS labels now use recycled materials for their facestock. Technological advancements have also enabled the development of specialized adhesives that support recycling processes without hindrance. These labels are not only durable but also visually appealing, with applications extending to tough environments, such as chemical drum labeling. - Revolutionary RFID Integration:

Radio-frequency identification (RFID) is transforming the PS label industry. By embedding RFID chips into labels, products can be tracked, authenticated, and safeguarded against counterfeiting. These “intelligent labels” are widely used across sectors to streamline data collection and enhance supply chain security. - Flexible and Reusable Options:

The use of detachable and repositionable films for facestock is on the rise. These films are particularly valuable for applications requiring high-speed labeling, such as in beverage packaging, as they can be removed and reapplied with ease. In the pharmaceutical industry, these films are preferred for their precision and compact design. - Aesthetic Excellence:

To grab consumers’ attention on crowded store shelves, PS labels offer a range of attractive designs and materials. These include textured specialty papers, vibrant metallized foils, clear or matte films, holographic variants, textiles, and even wood veneer. Label printers use techniques like embossing, foil stamping, die-cutting, and spot varnishing to create visually stunning labels. - Regional Highlights:

- North America dominated the market in 2023, holding a 35.94% share, driven by stringent food safety and healthcare labeling standards, a strong regulatory framework, and demand for premium packaging.

- Asia-Pacific is expected to grow at the fastest rate (CAGR 7.25%) through 2034, fueled by rapid industrialization, urbanization, and the booming e-commerce sector in countries like China, India, and Japan.

Notable Innovations from Industry Leaders

- In April 2023, Innovia Films launched Rayoface AQBSA, a coated white BOPP facestock film for PS labels. With a thickness of 58 microns and 91% opacity, it features a printable top layer and an adhesive-ready backside. It caters to sectors like food and beverage, personal care, and consumer goods.

- In August 2023, Avery Dennison introduced AD LinrSave and AD LinrConvert, a new range of linerless decorative PS labels. Using advanced micro-perforation technology, these labels reduce packaging waste, carbon emissions, and water usage while maintaining high performance and consumer appeal. This innovation supports the industry’s shift toward more sustainable and connected packaging solutions.

Buy Premium Global Insight: https://www.towardspackaging.com/price/5381

Get the latest insights on packaging industry segmentation with our Annual Membership – https://www.towardspackaging.com/get-an-annual-membership

If you have any questions, please feel free to contact us at sales@towardspackaging.com

Browse our Brand-New Journal:

https://www.towardshealthcare.com

https://www.towardsautomotive.com

For Latest Update Follow Us: https://www.linkedin.com/company/towards-packaging/

Get Our Freshly Printed Chronicle: https://www.packagingwebwire.com/