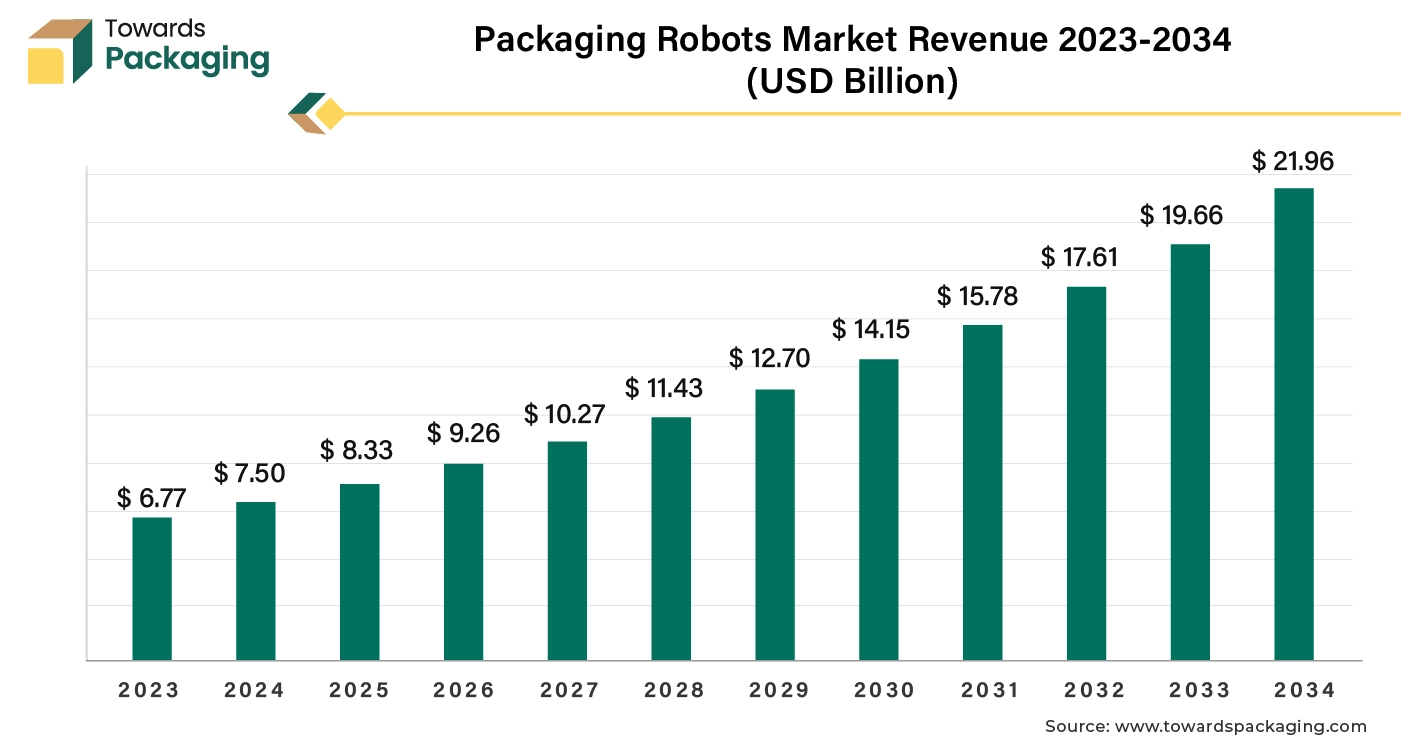

The global packaging robots market was valued at approximately USD 6.77 billion in 2023 and is expected to grow to about USD 21.96 billion by 2034, reflecting a compound annual growth rate (CAGR) of 11% from 2023 to 2034.

Download Statistical Data: https://www.towardspackaging.com/download-statistics/5270

Packaging robots can be programmed for various tasks, catering to diverse product types and packaging requirements. The key players operating in the market are focused on adopting inorganic growth strategies like acquisition and merger to develop advance technology for manufacturing packaging robots which is estimated to drive the global packaging robots market over the forecast period.

Major Key Insights of the Packaging Robots Market

- Asia Pacific dominated the packaging robots market in 2023.

- North America is expected to grow at a significant rate in the market during the forecast period.

- By gripper type, the clamp and claws segment dominated the market with the largest share in 2023.

- By service, pick & place segment is expected to grow at significant rate during the forecast period.

- By end user, the food and beverage segment dominated the packaging robots market in 2023.

Packaging Robots Market: Automated Packaging

Packaging robots are automated systems designed to perform various tasks in the packaging process of products across different industries. These robots enhance efficiency, accuracy, and speed while reducing labor costs and minimizing human error. There are different types of packaging robots which have been mentioned here as follows: articulated robots, delta robots, SCARA Robots, collaborative robots (Cobots), and mobile robots. Articulated Robots have rotary joints and can move in multiple axes, making them highly versatile for tasks like palletizing, picking, and placing. The packaging robots carry out function of sorting, filling, sealing, labeling, palletizing, and wrapping.

The sorting is carried out to organise products based on size type, or other criteria before packaging. Palletizing is done for stacking packaged products onto pallets for shipment and storage. The packaging robots provide various advantages like increased efficiency, consistency and precision, labor cost reduction, enhanced safety, space optimization and scalability. In conclusion, packaging robots are integral to modern manufacturing and logistics, streamlining operations and ensuring high-quality packaging. Their continued evolution promises even greater efficiency and adaptability in the future. The global packaging industry size is estimated to grow from USD 1.20 trillion in 2022 to reach an estimated USD 1.58 trillion by 2032, growing at a 3.16% CAGR between 2023 and 2032.

5 Key Factors Driving Packaging Robots Market Growth

- The key players operating in the market are focused on geographic expansion and launching their brand in other countries which is expected to drive the growth of the packaging robots market in the near future.

- Increasing focus on cost reduction and production efficiency can drive the specialty market growth further.

- Emerging markets and trends for packaging robots is expected to drive the growth of the global packaging robots market over the forecast period.

- Increasing regulatory support is estimated to drive the growth of the packaging robots market over the forecast period.

- Increasing in adoption of the advanced technology for the production of packaging robots is estimated to drive the growth of the global packaging robots market in the near future.

- Long-term cost savings from reduced labor and improved productivity are motivating companies to invest in robotic systems.

- The need for efficiency and reliability in supply chains has increased the adoption of robotics in packaging.

How Can AI Improve the Packaging Robots Industry?

Integrating AI into the packaging robotics industry can significantly enhance efficiency and accuracy. AI algorithms can optimize robot operations, allowing for faster and more precise packaging processes, reducing cycle times and improving throughput. Machine learning can enable real-time monitoring of packaging quality, detecting defects or inconsistencies and ensuring that products meet standards.

AI algorithms can optimize the movement and operations of robots, reducing downtime and increasing throughput. Predictive analytics can anticipate demand and adjust operations accordingly.

AI can analyze data from robots to predict failures before they occur, minimizing downtime and maintenance costs.

Machine learning can enable real-time monitoring of packaging quality, detecting defects or inconsistencies and ensuring that products meet standards.

AI-powered robots can quickly adjust to different products and packaging styles, allowing manufacturers to easily switch between various tasks without extensive reprogramming. AI-driven interfaces can simplify operations for human operators, making it easier to monitor and control robotic systems, thus improving overall user experience. AI can facilitate better communication and coordination between packaging robots and other parts of the supply chain, leading to improved inventory management and fulfillment processes.

By automating routine tasks, AI can allow human workers to focus on more complex, value-added activities, enhancing overall productivity. AI-driven interfaces can simplify operations for human operators, making it easier to monitor and control robotic systems, thus improving overall user experience.

By leveraging these AI capabilities, the packaging robotics industry can achieve greater agility, higher productivity, and improved product quality, ultimately leading to enhanced customer satisfaction and reduced operational costs.

Buy Premium Global Insight: https://www.towardspackaging.com/price/5270

Get the latest insights on packaging industry segmentation with our Annual Membership – https://www.towardspackaging.com/get-an-annual-membership

If you have any questions, please feel free to contact us at sales@towardspackaging.com

About Us

Towards Packaging is a leading global consulting firm specializing in providing comprehensive and strategic research solutions. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations. We stay abreast of the latest industry trends and emerging markets to provide our clients with an unrivalled understanding of their respective sectors. We adhere to rigorous research methodologies, combining primary and secondary research to ensure accuracy and reliability. Our data-driven approach and advanced analytics enable us to unearth actionable insights and make informed recommendations. We are committed to delivering excellence in all our endeavours. Our dedication to quality and continuous improvement has earned us the trust and loyalty of clients worldwide.

Browse our Brand-New Journal: