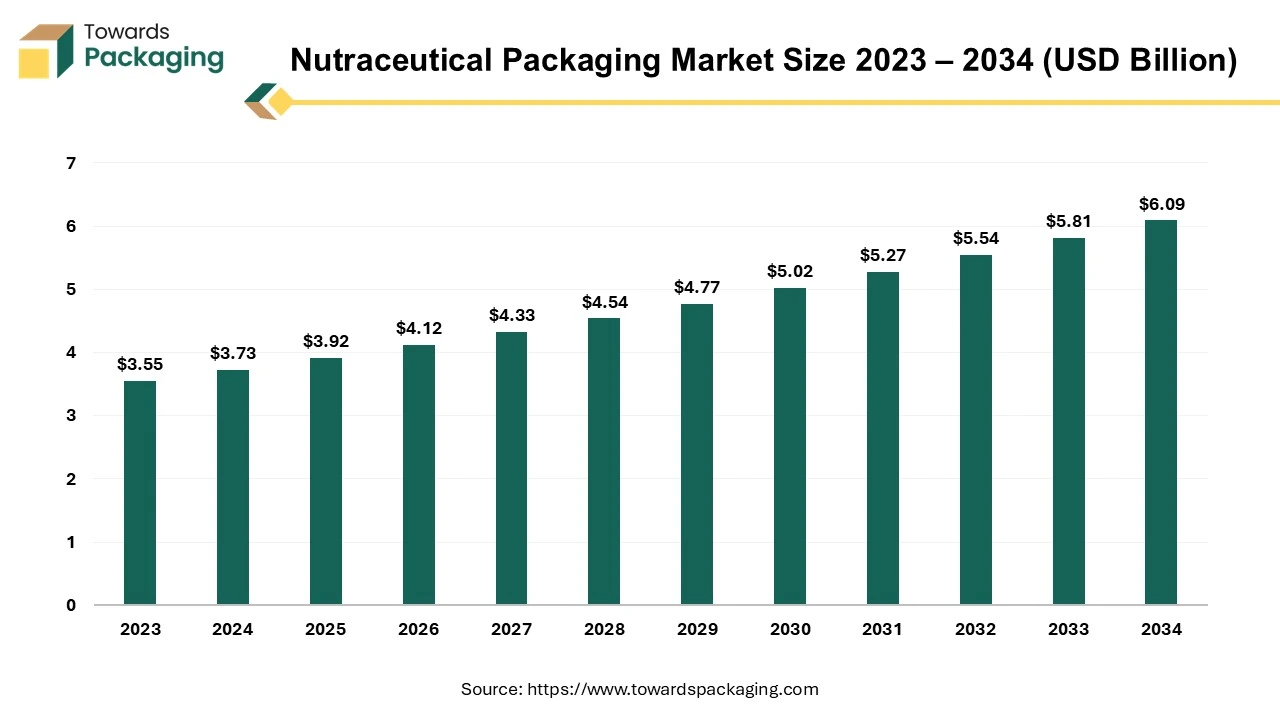

The nutraceutical packaging industry is evolving rapidly, driven by changing consumer demands, technological advancements, and growing concerns about environmental sustainability. As consumers increasingly prioritize health-conscious choices, packaging plays a pivotal role in communicating a brand’s commitment to quality, safety, and sustainability. The global nutraceutical packaging market is poised for significant growth, with its size expected to hit USD 6.09 billion by 2034, growing from USD 3.73 billion in 2024, expanding at a 5.1% CAGR from 2024 to 2034. Below, we explore the key trends that are shaping the future of the nutraceutical packaging market.

Get All the Details in Our Solution – Download Brochure: https://www.towardspackaging.com/download-brochure/5179

Sustainability and Eco-Friendly Solutions

One of the most significant shifts in the nutraceutical packaging industry is the growing emphasis on sustainability. As both consumers and companies seek to reduce their environmental footprint, the demand for biodegradable and recyclable packaging materials is rising. Brands are increasingly opting for plant-based components, recyclable plastics, and paper-based materials to minimize environmental impact. These eco-friendly options are not only in response to consumer preferences but also to address regulatory pressures aiming to reduce plastic waste. Manufacturers are innovating in materials that are both sustainable and functional, ensuring they meet the quality requirements of nutraceutical products while promoting a greener future.

Smart and Digital Packaging

With the rise of digital technology, smart packaging is becoming an integral part of the nutraceutical packaging landscape. Features such as serialization, QR codes, and NFC (Near Field Communication) tags are increasingly being incorporated into packaging solutions. These technologies allow consumers to verify the authenticity of products, ensuring that they are purchasing legitimate and safe nutraceuticals. In addition to product verification, smart packaging offers brands the ability to provide consumers with detailed product information, usage instructions, and even promotional offers through their smartphones. This added layer of transparency builds consumer trust while enhancing the overall customer experience.

Functional Features

The demand for packaging that offers enhanced functionality is also on the rise. Packaging solutions with tamper-evident seals, moisture barriers, and child-resistant closures are becoming more common as manufacturers seek to ensure product safety. These features provide peace of mind to consumers, ensuring that the products they purchase are secure and uncontaminated. Moisture barriers, in particular, are vital in preserving the quality of sensitive nutraceutical products, such as vitamins and supplements, which can degrade if exposed to humidity. As a result, these functional elements are now seen as standard in nutraceutical packaging, further elevating product integrity and consumer confidence.

Personalized and Clean Label Packaging

In response to the growing demand for transparency and healthier product choices, nutraceutical companies are embracing clean-label packaging. Clean-label packaging emphasizes transparency, allowing consumers to clearly see and understand what ingredients are included in the product. With an increasing number of health-conscious consumers, particularly Millennials and Gen Z, demanding more information about what they consume, clean-label packaging is becoming a powerful tool for building brand loyalty. It highlights the purity of the ingredients used, free from artificial additives or preservatives, and appeals to a growing market that values health, wellness, and transparency.

Adoption of Advanced Manufacturing Technologies

To meet the growing demands of the nutraceutical market, manufacturers are increasingly turning to advanced packaging technologies. Robotic automation and other cutting-edge manufacturing techniques are being integrated into the production process to improve efficiency, reduce costs, and maintain high-quality standards. Automated systems can help streamline packaging operations, ensuring faster turnaround times and consistent product packaging, while reducing human error. As manufacturers face the pressure of meeting consumer expectations and regulatory standards, automation provides a way to scale production while ensuring packaging quality remains high.

Invest in Our Premium Strategic Solution: https://www.towardspackaging.com/price/5179

Get the latest insights on packaging industry segmentation with our Annual Membership – https://www.towardspackaging.com/get-an-annual-membership

If you have any questions, please feel free to contact us at sales@towardspackaging.com

Browse our Brand-New Journal:

https://www.towardshealthcare.com

https://www.towardsautomotive.com

For Latest Update Follow Us: https://www.linkedin.com/company/towards-packaging/

Get Our Freshly Printed Chronicle: https://www.packagingwebwire.com/