Metalized Flexible Packaging Market Growth: Size, Share, and Key Companies

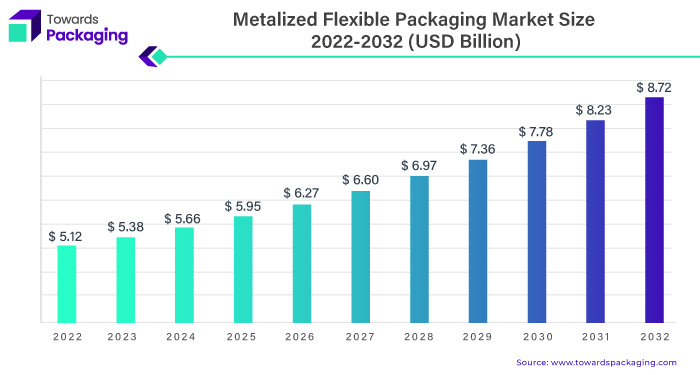

The global metalized flexible packaging market is projected to expand from USD 5.12 billion in 2022 to an estimated USD 8.72 billion by 2032, growing at a compound annual growth rate (CAGR) of 5.5% from 2023 to 2032.

Download Statistical Data: https://www.towardspackaging.com/download-statistics/5090

Key Insights into the Metalized Flexible Packaging Market

- The metalized flexible packaging market is expected to grow at a compound annual growth rate (CAGR) of 5.5% between 2023 and 2032.

- Metalized films are central to the evolution of metalized flexible packaging.

- Innovation is playing a key role in driving trends in metalized pouch packaging.

- Metalized flexible packaging is transforming the way food and beverages are packaged.

- The Asia Pacific region leads the metalized flexible packaging market with a 42% share.

- North America continues to influence the market’s direction, playing a strategic role in the growth of metalized flexible packaging.

Metalized flexible packaging typically consists of a metal-coated polymer film, with aluminum being the most commonly used metal. However, other metals like chromium and nickel are also used in the metallization process. The films are created by heating metals in a vacuum, causing the metal to condense onto polymer films, forming a shiny metallic surface similar to aluminum foil. These metalized films are lighter and more cost-effective than traditional aluminum foil due to their thinner profile, even though they share similar properties, such as high combustibility.

The rise in flexible packaging adoption is driven by several technological advancements, offering improved barrier capabilities and the ability to tailor packaging through various coatings, film types, and production methods. For example, seed packaging has evolved from basic containers to sophisticated, moisture-resistant packages that preserve seed quality by preventing moisture absorption. Dehydrated seeds, stored in these advanced containers, maintain their viability and vigor despite varying temperature and humidity conditions.

In the broader packaging industry, valued at approximately $500 billion globally, innovations in materials are enhancing product protection, shelf appeal, and sustainability. The flexible packaging market, expected to reach $278.9 billion by 2025, is growing due to consumer demand for convenient, protective packaging, with food being the largest sector, accounting for over 60% of the market. Key factors driving this growth include the rise of e-commerce, digital printing, and a focus on sustainability. One major innovation within this space is metalized flexible packaging.

This packaging type combines high-quality flexible films like polyethylene, polypropylene, and polyester, which are reinforced by a thin layer of metal, typically aluminum. The metallization process adds a protective barrier that shields contents from moisture, light, and oxygen. Adhesive layers ensure that the metal layer remains bonded to the film, and additional processes like printing and lamination offer customization, branding, and durability.

The metalized layer provides several benefits. It offers strong protection against external elements, extending shelf life and keeping products fresh. Its reflective nature blocks harmful UV rays, making it perfect for light-sensitive products. Additionally, the thermal insulation properties help preserve temperature-sensitive items.

Recent Developments in the Metalized Flexible Packaging Market

- October 2022: The Mondi Group partnered with a leading Norwegian pet food company to relaunch their premium Appetite brand with recyclable high-barrier packaging. The dry cat and dog food will now be packed and stored in recyclable Mondi Flexi bags.

- August 2023: Mondi PLC invested €400 million in a new kraft paper machine to meet the increasing demand for sustainable, paper-based flexible packaging materials.

- June 2023: Oben Group announced the acquisition of Terphane, a subsidiary of Tredegar Corporation, through a Share Purchase Agreement. Terphane manufactures flexible packaging films.

- August 2023: Madura Tea, an Australian tea company, reduced its environmental impact by switching from metallized OPP (oriented polypropylene) packaging to more eco-friendly flexible packaging paper. This change, in collaboration with Koehler Paper and Gundlach Packaging Group, will replace all metallized packaging with the new, sustainable material.

- August 2023: Amcor Limited acquired Phoenix Flexibles, a flexible packaging company based in Gujarat, India, with one production unit. This strategic acquisition aims to expand Amcor’s presence in the growing Indian market.

Buy Premium Global Insight: https://www.towardspackaging.com/price/5090

Get the latest insights on packaging industry segmentation with our Annual Membership – https://www.towardspackaging.com/get-an-annual-membership

If you have any questions, please feel free to contact us at sales@towardspackaging.com

Browse our Brand-New Journal:

https://www.towardshealthcare.com

https://www.towardsautomotive.com

For Latest Update Follow Us: https://www.linkedin.com/company/towards-packaging/

Get Our Freshly Printed Chronicle: https://www.packagingwebwire.com/