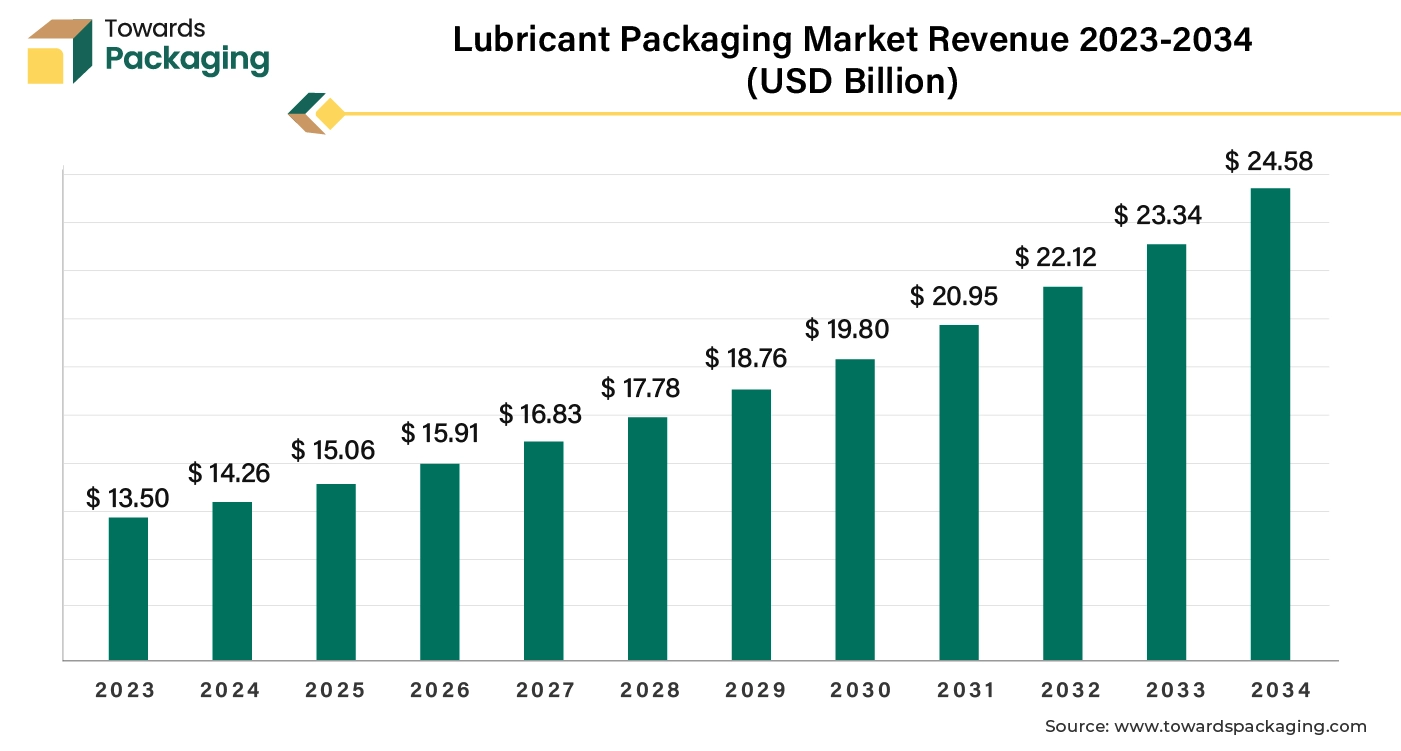

The global lubricant packaging market has been experiencing significant growth, reaching a market size of US$ 13.50 billion in 2023. This sector is poised for further expansion, with projections indicating that it will hit approximately US$ 24.58 billion by 2034, growing at a CAGR of 5.6% during the forecast period from 2024 to 2034. This growth is driven by a rising demand for high-quality, innovative packaging solutions that protect lubricants, maintain product integrity, and enhance brand value.

Download Statistical Data: https://www.towardspackaging.com/download-statistics/5269

Lubricant Packaging Market: Overview and Revenue Projections

Lubricant packaging plays a critical role in preserving the quality and effectiveness of lubricants, ensuring they are stored, transported, and dispensed safely. The market includes a wide range of packaging types such as bottles, jars, drums, barrels, pails, containers, and flexible packaging. These materials are used across various industries, including automotive, industrial machinery, and aviation, with increasing demand for innovative, eco-friendly solutions.

Key Insights for 2023:

- Asia Pacific dominated the global lubricant packaging market in 2023, driven by rapid industrialization and demand in the automotive sector.

- North America is anticipated to experience significant growth during the forecast period, due to advances in packaging technology and a strong focus on sustainability.

- The engine oil segment held the largest market share in 2023 by product type, fueled by increased automotive sales and maintenance activities.

- Drums are expected to grow at a significant rate by 2034, reflecting their widespread use in bulk industrial lubricant packaging.

- Plastic remains the dominant material in lubricant packaging due to its versatility, cost-effectiveness, and adaptability to recyclable and biodegradable options.

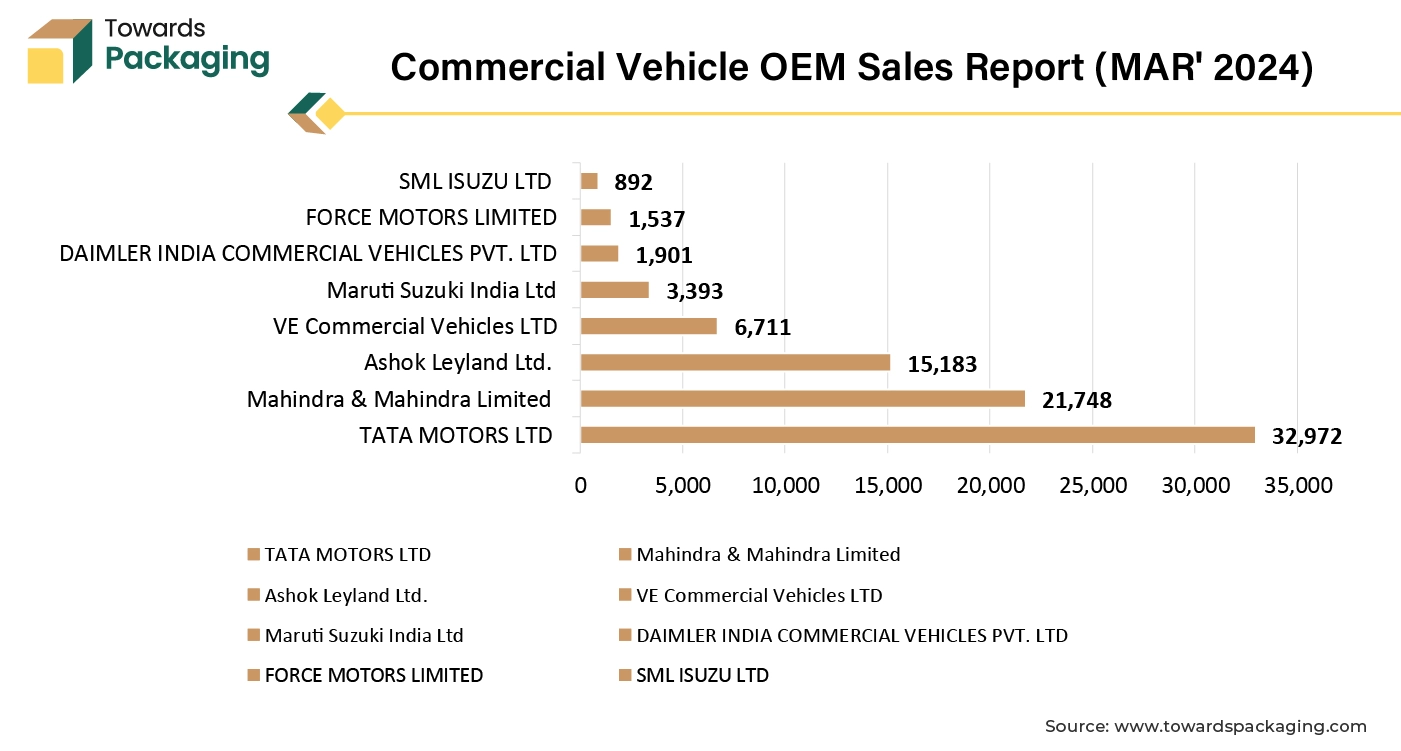

- The automotive industry emerged as the top end-use industry, demonstrating its heavy reliance on reliable lubricant packaging.

Lubricant Packaging Market: Safeguarding Quality and Efficiency

Lubricants are essential for minimizing friction between surfaces, thereby enhancing the performance and longevity of mechanical components. Packaging is crucial for maintaining the purity and efficacy of these products by protecting them from external contaminants such as moisture, dust, and air exposure. Additionally, lubricant packaging is designed to comply with stringent safety regulations, incorporating features such as child-resistant caps and tamper-evident seals.

Packaging Types for Lubricants:

- Bottles and Jars: Primarily used for consumer products like motor oils and household lubricants. They are available in various sizes and materials to meet specific market needs.

- Drums and Barrels: These are common for bulk industrial lubricants, providing robust, large-capacity solutions for the transportation and storage of oils and greases.

- Pails and Containers: Ideal for medium-sized lubricant quantities, these are used across both industrial and commercial applications.

- Flexible Packaging: A lightweight, cost-effective option, flexible packaging is gaining traction for certain specialty applications. It is particularly advantageous due to its space-saving and eco-friendly properties.

Ensuring Product Integrity:

Lubricant packaging is engineered to act as a protective shield that preserves the product’s chemical composition and performance throughout its lifecycle. Innovations in material science have resulted in recyclable and biodegradable packaging solutions, aligning with global trends toward sustainability and environmental responsibility. Additionally, lubricant packaging often incorporates advanced labeling systems that provide critical product information, including usage instructions, safety warnings, and compliance details.

Top 5 Factors Driving Lubricant Packaging Market Growth

1. Geographic Expansion and Brand Launches

Key players in the lubricant packaging market are pursuing geographic expansion strategies to tap into emerging markets and new consumer bases. Companies are also increasingly focusing on mergers and acquisitions to broaden their product portfolios and enhance their global footprint. This expansion is expected to fuel growth, particularly in Asia-Pacific and Latin America.

2. Cost Reduction and Production Efficiency

Companies are under pressure to cut costs while maintaining high-quality standards. By adopting advanced manufacturing technologies and innovative packaging solutions, lubricant manufacturers can significantly reduce production costs. This trend is expected to drive further growth, especially in the automotive and industrial sectors.

3. Emerging Markets and New Trends

Emerging markets, particularly in Asia-Pacific and Africa, are poised for significant growth due to the industrial boom and rising automotive sales. Furthermore, trends such as eco-friendly packaging, recyclable materials, and biodegradable solutions are becoming increasingly important as companies respond to environmental regulations and consumer demand for sustainable products.

4. Increasing Regulatory Support

The lubricant packaging market is benefiting from government initiatives and regulatory frameworks that promote the use of environmentally friendly materials and processes. Regulations aimed at reducing plastic waste and promoting recycling are expected to further stimulate market growth. Companies are responding by developing innovative, sustainable packaging that complies with environmental standards.

5. Adoption of Advanced Technology

Technological advancements in manufacturing processes and packaging materials are revolutionizing the lubricant packaging industry. Automated systems and smart packaging solutions are being integrated into the production lines, increasing the efficiency, precision, and speed of the packaging process. Innovations such as smart sensors, real-time tracking, and AI-driven automation are expected to enhance the capabilities of lubricant packaging, ensuring that products are safely delivered to consumers.

Key Companies Leading the Lubricant Packaging Market

Several global companies are dominating the lubricant packaging market, focusing on innovation and geographic expansion to maintain their competitive edge. These include:

- Greif, Inc.: Known for their durable, bulk industrial packaging solutions, Greif is a leader in the drums and barrels segment, supplying robust containers for large-scale lubricant storage.

- Mauser Group B.V.: Mauser focuses on sustainable packaging options and offers a wide range of recyclable and environmentally friendly solutions for the lubricant industry.

- SCHÜTZ GmbH & Co. KGaA: This company specializes in the production of intermediate bulk containers (IBCs) and is known for its advanced container designs for lubricant storage and transport.

- Berry Global, Inc.: A global leader in plastic packaging solutions, Berry Global is focusing on the development of innovative, lightweight packaging that is both durable and sustainable.

- Time Technoplast Ltd.: Specializing in a variety of packaging formats, including rigid plastics and composite packaging, Time Technoplast provides flexible and adaptable solutions for lubricant manufacturers across multiple industries.

Future Outlook: Lubricant Packaging Market 2024 – 2034

The global lubricant packaging market is expected to witness steady growth over the next decade, with increasing demand from the automotive and industrial sectors being the primary drivers. With a growing emphasis on sustainability, manufacturers are investing in green technologies and eco-friendly packaging materials, further driving innovation in the market.

Key Trends to Watch:

- Sustainability: The use of biodegradable materials and recyclable packaging will continue to grow, as consumers and regulators push for more environmentally friendly solutions.

- Smart Packaging: The integration of smart technologies such as RFID tags and IoT sensors into lubricant packaging will enhance product tracking, inventory management, and compliance monitoring.

- Customization: As customer preferences shift, lubricant packaging will become increasingly customizable to meet the unique requirements of different industries and applications.

The lubricant packaging market is set for significant growth, driven by innovations in sustainability, technological advancements, and the rising demand for premium packaging solutions. With key players focusing on expanding their geographic presence and improving packaging efficiency, the market will continue to evolve and thrive.

Buy Premium Global Insight: https://www.towardspackaging.com/price/5269

Get the latest insights on packaging industry segmentation with our Annual Membership – https://www.towardspackaging.com/get-an-annual-membership

If you have any questions, please feel free to contact us at sales@towardspackaging.com

About Us

Towards Packaging is a leading global consulting firm specializing in providing comprehensive and strategic research solutions. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations. We stay abreast of the latest industry trends and emerging markets to provide our clients with an unrivalled understanding of their respective sectors. We adhere to rigorous research methodologies, combining primary and secondary research to ensure accuracy and reliability. Our data-driven approach and advanced analytics enable us to unearth actionable insights and make informed recommendations. We are committed to delivering excellence in all our endeavours. Our dedication to quality and continuous improvement has earned us the trust and loyalty of clients worldwide.

Browse our Brand-New Journal:

https://www.towardshealthcare.com

https://www.towardsautomotive.com

For Latest Update Follow Us: https://www.linkedin.com/company/towards-packaging/

Get Our Freshly Printed Chronicle: https://www.packagingwebwire.com/