Industrial Foam Market Overview: Companies and Regional Insights

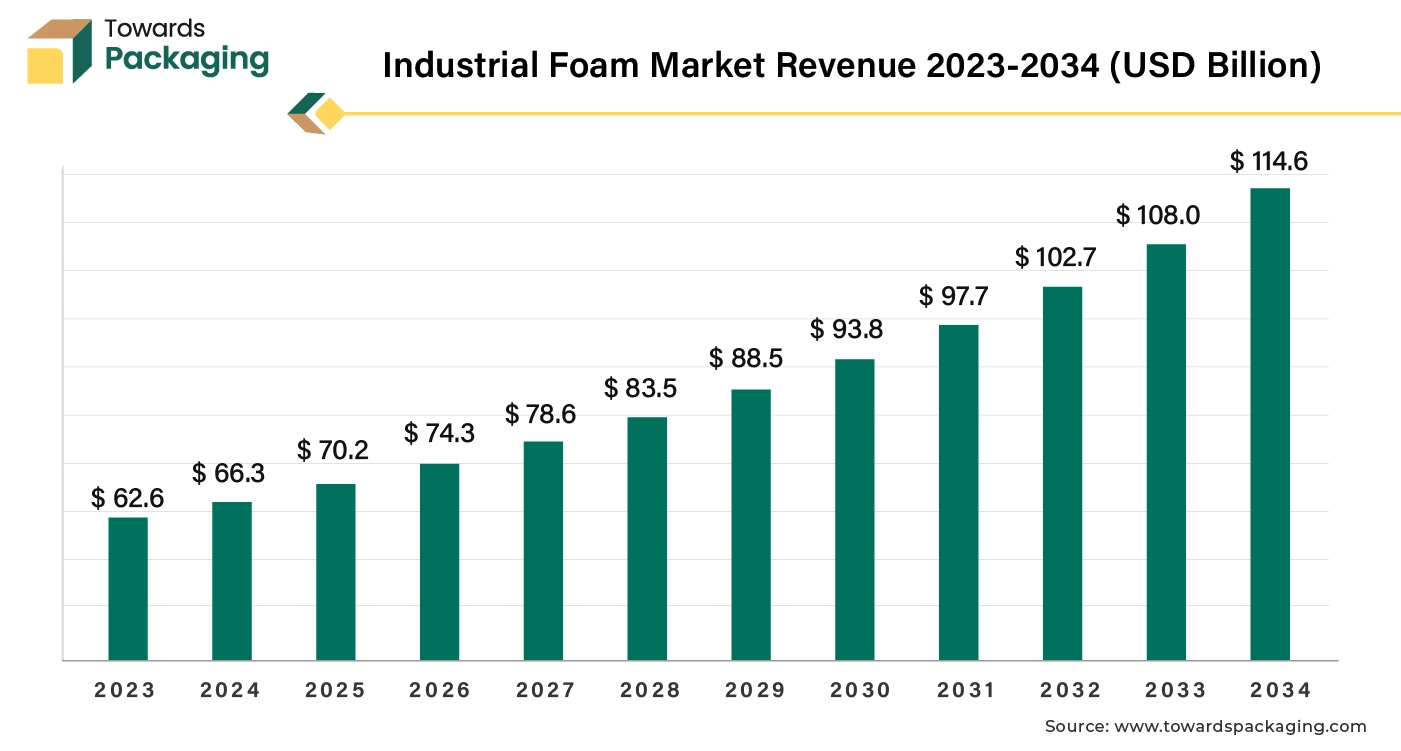

The industrial foam market was valued at USD 62.6 billion in 2023, and is projected to grow to USD 66.3 billion in 2024, eventually reaching around USD 114.6 billion by 2034. This growth represents a compound annual growth rate (CAGR) of 5.65% from 2025 to 2034. The expanding use of industrial foam in various industries is a key factor driving this market’s growth.

Download Statistical Data: https://www.towardspackaging.com/download-statistics/5280

The demand for industrial foam packaging is increasing, mainly due to its broad range of applications across industries like automotive, construction, medical, healthcare, and packaging.

Key Insights from the Industrial Foam Market:

- Asia Pacific led the market in 2023 with the largest market share.

- North America is expected to experience the highest growth rate during the forecast period.

- Flexible foam dominated the market in 2023.

- The rigid foam segment is expected to grow the fastest in the coming years.

- Polyurethane foam was the leading material in 2023.

- Polystyrene foam is expected to grow at the fastest rate moving forward.

- The building and construction sector led the market in 2023.

- The aerospace industry is expected to grow at the highest rate during the forecast period.

Industrial foam is used across a range of industries for purposes such as packaging, insulation, cushioning, and structural applications. It is made by trapping gas in a liquid or solid substance, creating bubbles. The most common types of industrial foam include polyurethane, polyethylene, polystyrene, and polyvinyl chloride. The increasing demand for foam can be attributed to its lightweight nature, insulation properties, and versatility, which make it suitable for numerous uses in industries like construction, automotive, packaging, consumer goods, and healthcare.

In addition, advancements in foam manufacturing are boosting the industry’s growth. Innovations are improving foam’s performance and sustainability, with an increasing focus on biodegradable and recycled foams. For example, the global packaging market is expected to grow from USD 1.20 trillion in 2022 to USD 1.58 trillion by 2032, driven by a 3.16% CAGR between 2023 and 2032.

The Role of Artificial Intelligence in the Industrial Foam Market

Artificial Intelligence (AI) is transforming industries, and its integration into the industrial foam sector is proving to be a major game-changer. AI is helping manufacturers enhance production processes, improve efficiency, and reduce operational costs. With AI-driven analytics, manufacturers can optimize their operations, minimize waste, and improve product quality by reducing human errors. AI can also streamline inventory management and optimize supply chains. By combining AI with technologies like machine learning and the Internet of Things (IoT), companies can achieve smoother operations and a competitive edge. Furthermore, AI aids in predictive maintenance and analyzing market trends, consumer preferences, and patterns, offering valuable insights for businesses.

Key Insights from the Industrial Foam Market:

- Asia Pacific held the largest share of the industrial foam market in 2023.

- North America is expected to see the highest growth rate during the forecast period.

- The flexible foam segment was the leading category in 2023.

- The rigid foam segment is projected to grow the fastest in the coming years.

- Polyurethane foam dominated the market in 2023.

- Polystyrene foam is expected to grow at the fastest pace in the future.

- The building and construction industry led the market in 2023.

- The aerospace sector is expected to grow the fastest during the forecast period.

AI’s Impact on the Industrial Foam Market

Artificial Intelligence (AI) is transforming various industries, and the industrial foam market is no exception. As AI continues to be integrated into different sectors, it is reshaping how processes work in the foam industry. AI-driven technologies play a crucial role in improving manufacturing processes, boosting efficiency, and cutting operational costs. Through AI-powered analytics, manufacturers can optimize productivity, reduce waste, and minimize the risks of inconsistent quality and human error. AI also streamlines inventory management and supply chain operations. When combined with machine learning or the Internet of Things (IoT), AI opens up new opportunities for smooth and efficient industrial foam processes. Additionally, AI can assist in predictive maintenance, identifying market trends, and understanding consumer preferences, providing companies with a competitive advantage.

Factors Driving Growth in the Industrial Foam Market

- The rise in construction activities, particularly in developing economies, is driving the demand for insulation materials like polyurethane and polystyrene foams.

- The growth of e-commerce and the need for protective packaging materials is contributing to the increased demand for industrial foams.

- Innovations in foam production technologies, such as eco-friendly manufacturing and advanced molding techniques, are improving product performance and reducing costs.

- Rapid urbanization in emerging economies is boosting construction activities, further increasing the need for insulation and structural foams.

Buy Premium Global Insight: https://www.towardspackaging.com/price/5280

Get the latest insights on packaging industry segmentation with our Annual Membership – https://www.towardspackaging.com/get-an-annual-membership

If you have any questions, please feel free to contact us at sales@towardspackaging.com

Browse our Brand-New Journal:

https://www.towardshealthcare.com

https://www.towardsautomotive.com

For Latest Update Follow Us: https://www.linkedin.com/company/towards-packaging/

Get Our Freshly Printed Chronicle: https://www.packagingwebwire.com/