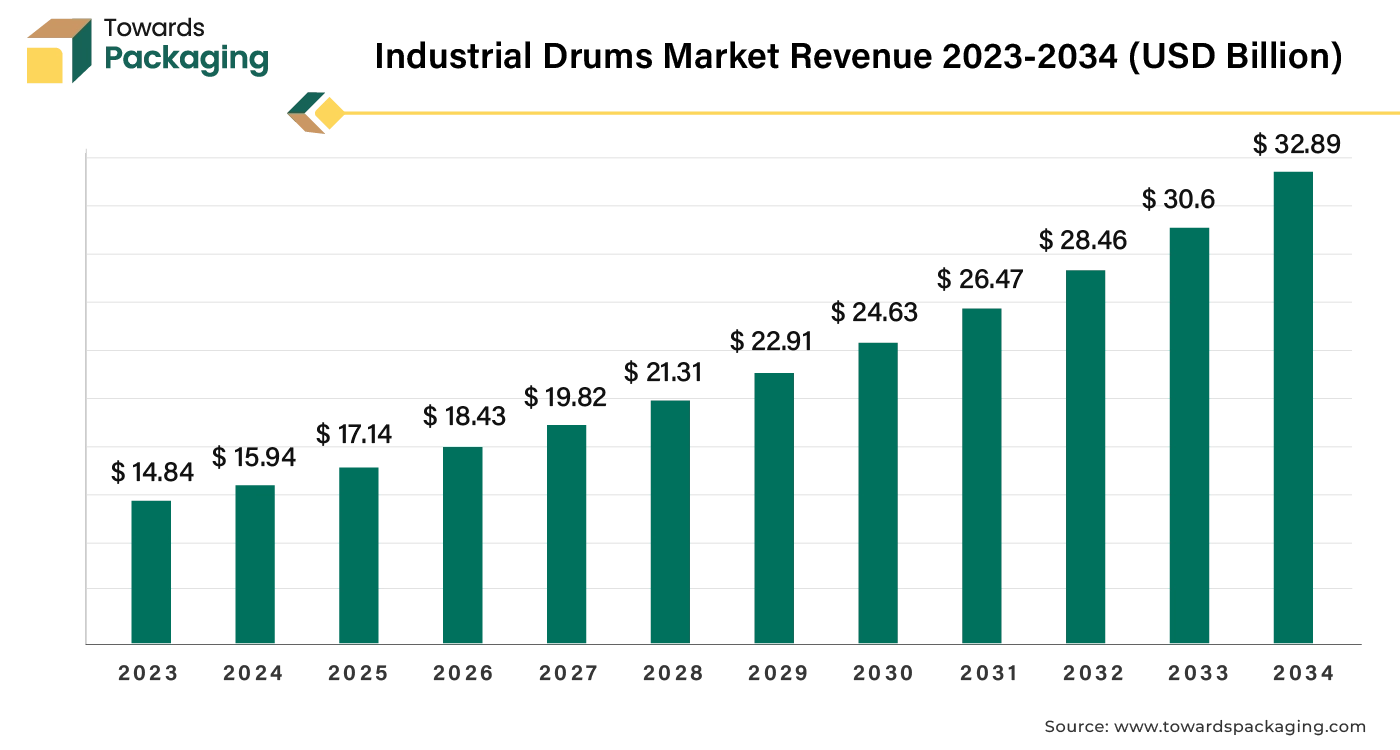

The global industrial drums market size reached USD 15.94 billion in 2024 and is projected to hit around USD 32.89 billion by 2034, expanding at a CAGR of 7.35% during the forecast period from 2024 to 2034. The key players operating in the market are focused on adopting inorganic growth strategies like merger for designing and introducing new technology industrial drums in market, which is estimated to drive the growth of the industrial drums market over the forecast period.

Download Statistical Data: https://www.towardspackaging.com/download-statistics/5232

Industrial Drums Market Key Takeaways

- Asia Pacific dominated the industrial drums market in 2023.

- North America is expected to grow at a significant rate in the market during the forecast period.

- By product type, the steel drums segment dominated the market with the largest share in 2023.

- By capacity, the 100 to 250 liters segment dominated the industrial bulk packaging market in 2023.

- By End Use, chemicals segment shown the significant growth rate during the forecast period.

Industrial Drums Market Overview

Commercial Drums are large, cylindrical industrial containers known as “industrial drums” are mostly used for storage and transportation. Industrial drums, one of the earliest forms of container, are used mostly for bulk products storage and transportation (mostly liquids). Industrial drums are affordable, durable, and strong. Above all, they work well to guarantee that the items kept inside are kept safe from harm and contaminates. These drums’ robust features provide effective storage while still being environmentally friendly. They are typically made of materials like steel, plastic, or fiberboard. Steel drums are sturdy and can be either carbon steel or stainless steel. They are often used for hazardous materials, chemicals, and heavy-duty applications. They come in different gauges and can be either open-head or tight-head. Plastic drum are made from high-density polyethylene (HDPE) or other plastic materials, these drums are lightweight, resistant to corrosion, and suitable for chemicals, food products, and pharmaceuticals.

They also come in open-head and tight-head varieties. Fiber drums are constructed from fiberboard or composite materials, these are lighter than metal drums and are used for dry bulk goods like powders and granules. They are less durable than metal or plastic drums and are often used for non-hazardous materials. Open-head drums have a removable lid secured with a ring or clamp. They are useful for products that need to be accessed frequently or require filling and emptying. Tight-head drums also known as closed-head drums, these have a non-removable lid with small bungs for filling and dispensing.

Drums typically feature bottom and top rims, sometimes known as chines. The majority of steel drums feature plastic or metal rings or rolling hoops for reinforcement. This gives them enough strength to allow them to be easily flipped over and rolled when loaded down with heavy objects, such as liquids. Drums may be balanced, tilted, and rolled on their bottom rim across short to medium distances. The torque, or rolling force, is provided by a two-handed top grip that is also used to rotate the drum. The global packaging market size is estimated to grow from USD 1.20 trillion in 2022 to reach an estimated USD 1.58 trillion by 2032, growing at a 3.16% CAGR between 2023 and 2032.

Top 5 Factors to Shape the Industrial Drums Market to Grow

- Increasing in adoption of the advanced technology for the production of liquid carton packaging is estimated to drive the growth of the global industrial drums market in the near future.

- The key players operating in the market are focused on geographic expansion and launching their brand in other countries which is expected to drive the growth of the global industrial drums market in the near future.

- Emerging markets and trends for liquid carton packaging is expected to drive the growth of the global industrial drums market over the forecast period.

- Increasing regulatory support is estimated to drive the growth of the market over the forecast period.

- Increasing focus on cost reduction and production efficiency can drive the specialty market growth further.

How Can AI Improve the Industrial Drums Industry?

AI can analyze data from sensors to predict when drums or related equipment will require maintenance or replacement. This minimizes downtime and reduces operational costs, leading to increased efficiency and customer satisfaction. AI-driven vision systems can detect defects or inconsistencies in drum manufacturing, ensuring higher quality products and reducing waste. Improved product reliability can boost customer confidence and expand market share. AI can enhance inventory management and demand forecasting, leading to more efficient production schedules and reduced excess inventory. This responsiveness can improve profitability and competitiveness. AI can enable more flexible manufacturing processes, allowing for custom designs and specifications based on customer needs. This can attract new clients looking for tailored solutions and expand market opportunities. In the industrial drums industry, AI can optimize production processes for energy usage, reducing costs and environmental impact.

This can appeal to environmentally conscious customers and comply with regulatory standards. AI can analyze industrial drums market trends and customer preferences, providing valuable insights for strategic decision-making and product development. This helps companies adapt to changing demands and identify new growth opportunities. AI can analyze market trends and customer preferences, providing valuable insights for strategic decision-making and product development. This helps companies adapt to changing demands and identify new growth opportunities. By leveraging AI, companies in the industrial drums industry can enhance their operational efficiency, product quality, and market responsiveness, driving overall growth in the industrial drums market.

Rockwell’s Case Study: A Pioneer in Smart Manufacturing

For instance,

- In March 2024, Rockwell Automation, Inc., digital transformation and industrial automation company, revealed the findings of the ninth annual “State of Smart Manufacturing Report,” which provides insightful information on trends, difficulties, and strategies for manufacturers throughout the world. More than 1,500 participants from 17 nations, including the U.K., France, Germany, Italy, and Spain, were polled for the study. This paper has numerous findings, but three stand out in particular: the manufacturing industry is entering a new phase of growth, technology is being used to give workers superpowers, and operational resilience is becoming more and more important.

According to manufacturers, Al is the most important capability that will lead to the greatest commercial results. In 2024, 79% of manufacturers in the U.K. anticipate using generative aluminium (GenAl) in their operations. U.K. firms anticipate using Al and ML in advanced analytics at a rate of 94%, which is higher than the global average of 91%. The biggest obstacle to integrating smart manufacturing technology in the U.K. is a lack of skill set, with 33% of respondents-the highest rate among all European nations polled.

Compared to Germany’s 41% and France’s 40%, only 25% of U.K. manufacturers believe they don’t have the trained labor force to outperform the competition over the next 12 months. Businesses reported a 30% year-over-year growth in technology spending throughout Europe. The greatest percentage of corporations in Europe, 73% of U.K. businesses invest between 21% and 50% of their operational budget in technology. According to 34% of U.K. businesses, management at top organizations uses data to create better Al and ML applications.

Rapid Expansion of Industries to Support the Market’s Growth

The Increasing industrial activities, particularly in sectors like chemicals, pharmaceuticals, and food and beverages, drive demand for industrial drums for storage and transportation of various materials. The rise in global trade and logistics increases the need for durable packaging solutions, including industrial drums, to handle and transport bulk goods across borders. Innovations in drum materials and designs, such as corrosion-resistant coatings and sustainable materials, enhance the functionality and appeal of industrial drums in various industries. Advancements in drum manufacturing technology improve the strength, safety, and efficiency of industrial drums. Rapid industrialization in emerging economies increases the demand for industrial drums in these regions. The key players operating in the pharmaceutical company are focused on adopting inorganic growth strategies like partnership to develop pharmaceutical packaging drums and other solutions, which is estimate to drive the growth of the industrial drums market over the forecast period.

For instance,

- In January 2024, Bormioli Pharma, a company focused on providing medical devices and pharmaceutical packaging signed partnership with Loop Industries, Inc., a clean technology company focused on manufacturing 100% recycled plastic products, to develop pharmaceutical packaging drums less than 100 liters with 100% recycled virgin quality Loop polyethylene terephthalate (PET) resin.

Furthermore, in March 2024, SOLIZE India, technology solution providing company signed partnership with Scapos AG, engineering solutions and software company, for revolutionising industrial packaging designs.

High Cost of Initial Investment and Availability of Alternatives Options to Hamper Market Growth

The primary factor restricting the market’s expansion is the substantial initial outlay needed for the production and acquisition of industrial drums. A lot of small and medium-sized businesses also need to produce more drums; therefore, they choose less expensive options. Additionally, the weight of these drums has a big impact on the cost of shipping. Further impeding the growth of the market is the fact that manufacturers are choosing lighter packaging options due to the high shipping costs associated with hefty drums for long-distance transportation. The availability of different bulk containers, flexi tanks, and intermediate bulk containers (BC) would potentially restrict the market’s growth.

Expansion of End-users to Offer Multiple Opportunities to the Market

Industrial drums are affordable, robust, and long-lasting. Above all, their efficacy is in guaranteeing the comprehensive safeguarding of the merchandise kept within against harm and pollution. These drums are environmentally sustainable in addition to providing effective storage thanks to their robust characteristics. Drums are a great option for storing and transporting items in a variety of sectors because of their properties. The chemical industries have increased their demand for these drums since they are frequently composed of high-density polyethylene or steel, which offers outstanding chemical resistance and prevents leaks or spills. Additionally, these drums are a crucial means of transportation for bulk materials, liquids, and powders in the food and beverage industry, which contributes to the industrial drums market growth.

Buy Premium Global Insight: https://www.towardspackaging.com/price/5232

Get the latest insights on packaging industry segmentation with our Annual Membership – https://www.towardspackaging.com/get-an-annual-membership

If you have any questions, please feel free to contact us at sales@towardspackaging.com

About Us

Towards Packaging is a leading global consulting firm specializing in providing comprehensive and strategic research solutions. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations. We stay abreast of the latest industry trends and emerging markets to provide our clients with an unrivalled understanding of their respective sectors. We adhere to rigorous research methodologies, combining primary and secondary research to ensure accuracy and reliability. Our data-driven approach and advanced analytics enable us to unearth actionable insights and make informed recommendations. We are committed to delivering excellence in all our endeavours. Our dedication to quality and continuous improvement has earned us the trust and loyalty of clients worldwide.

Browse our Brand-New Journal:

https://www.towardshealthcare.com

https://www.towardsautomotive.com

For Latest Update Follow Us: https://www.linkedin.com/company/towards-packaging/

Get Our Freshly Printed Chronicle: https://www.packagingwebwire.com/