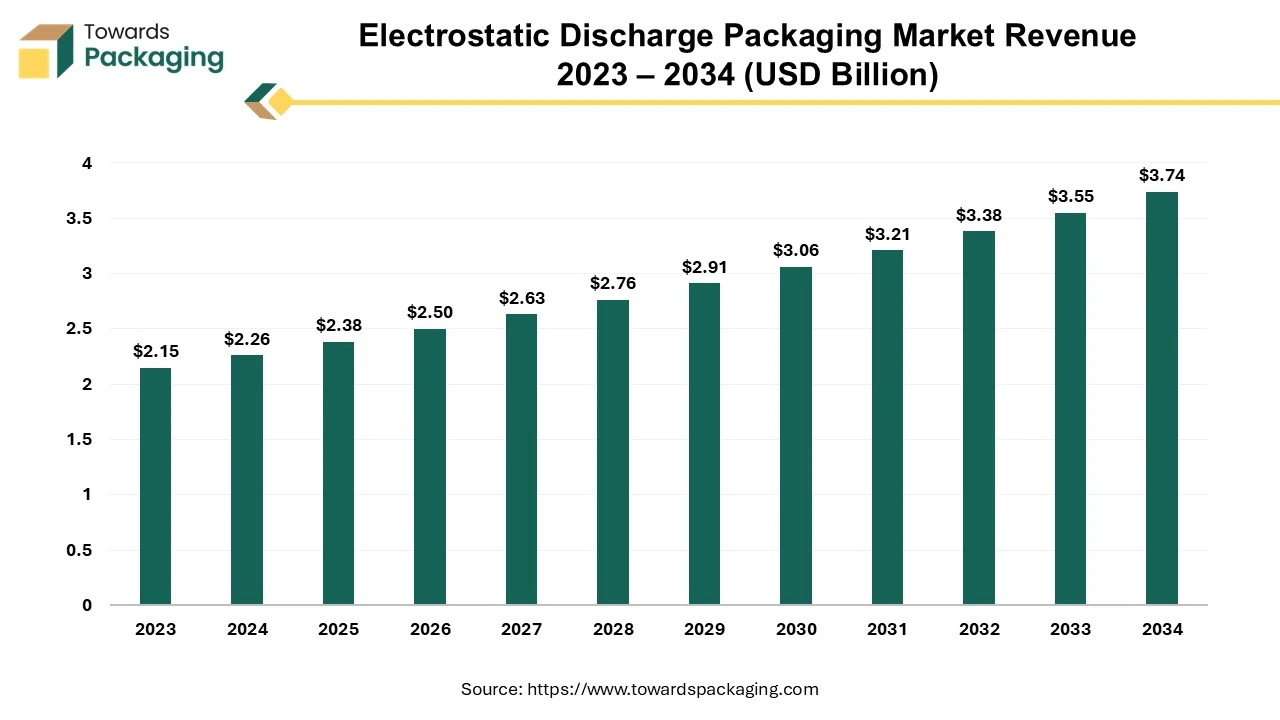

The global Electrostatic Discharge (ESD) packaging market reached a value of US$ 2.15 billion in 2023 and is poised for significant expansion. It is projected to reach US$ 3.74 billion by 2034, growing at a Compound Annual Growth Rate (CAGR) of 5.15% during the forecast period from 2024 to 2034. This growth is attributed to the increasing demand for electronic devices and the rising need for protective packaging solutions to safeguard sensitive electronic components from static discharge.

Get All the Details in Our Solution – Download Brochure: https://www.towardspackaging.com/download-brochure/5364

Electrostatic Discharge Packaging Market Revenue (2023–2034)

The adoption of inorganic growth strategies, including mergers and acquisitions by key players, is expected to fuel market growth. These strategies enable companies to enhance their technological capabilities for producing advanced electrostatic discharge packaging, further boosting the market’s development.

Major Key Insights of the Electrostatic Discharge Packaging Market

- Regional Dynamics: Asia Pacific dominated the electrostatic discharge packaging market in 2023. North America is expected to witness substantial growth throughout the forecast period.

- Product Types: The bags segment held the largest market share in 2023 and is expected to continue its dominance.

- Material & Additive Types: Conductive and dissipative polymers are anticipated to see significant growth during the forecast period due to their effectiveness in preventing electrostatic discharge.

- Application Insights: The electrical and electronic component segment was the leading application in the market in 2023, reflecting the importance of ESD packaging in electronics manufacturing and storage.

- End-User Base: The electrical and electronics industry is the largest consumer of electrostatic discharge packaging solutions globally, driven by the widespread use of sensitive electronic devices that require protection during transportation and storage.

Electrostatic Discharge Packaging: Safeguarding Electronics

Electrostatic Discharge (ESD) refers to the sudden flow of electricity between two objects at different electrical potentials, usually caused by direct contact or proximity. For industries handling delicate electronic components, such as semiconductors, microchips, and other sensitive electronics, ESD poses a significant risk. Even a tiny amount of static electricity can cause irreversible damage, malfunctions, or reduced performance of these devices.

This is where ESD packaging becomes crucial. ESD packaging is specifically designed to protect electronic components from static discharge by using materials that either dissipate static charges or shield components from electrostatic buildup. Common types of ESD packaging include bags, trays, boxes, films, and foams, each offering varying levels of protection depending on the sensitivity of the component.

Key Drivers of Market Growth

1. Rising Demand for Electronic Devices

The growing demand for consumer electronics, including wearables, smartphones, laptops, and other connected devices, has spurred the need for advanced protective packaging solutions. The proliferation of electronic gadgets has directly driven the electrostatic discharge packaging market, as manufacturers aim to prevent damage to delicate components.

For example, in September 2024, Apple Inc. launched its iPhone 16 series, which includes models like the iPhone 16, iPhone 16 Pro, and iPhone 16 Pro Max. The introduction of new electronic devices, such as the Apple Watch Series 10 and Ultra 3 model, has created an increased need for ESD packaging to ensure safe transport and storage.

2. Technological Advancements in ESD Packaging

The adoption of advanced technology for producing ESD packaging has become a key driver of the market. The continuous miniaturization of electronic components requires packaging solutions that offer higher protection and precision. This drives demand for specialized materials like conductive and dissipative polymers, which provide reliable protection.

3. Regulatory Support

Governments and regulatory bodies worldwide are increasingly emphasizing the importance of ESD-safe packaging. Many industries, such as semiconductors, aerospace, and automotive, face strict regulations that mandate the use of ESD-safe packaging. These regulations further promote the adoption of electrostatic discharge packaging solutions, driving market growth.

4. Cost Reduction and Production Efficiency

As manufacturers focus on cost reduction and efficiency in production processes, the demand for cost-effective and reliable ESD packaging solutions is expected to rise. This trend is likely to foster growth in the electrostatic discharge packaging sector.

Market Trends

1. Integration of Smart Technologies

The rise of Internet of Things (IoT) devices, smart homes, and connected systems has increased the demand for sensitive electronic components. These components require advanced protection during handling and transportation, thus boosting the need for specialized ESD packaging.

2. Sustainability and Eco-Friendly Packaging

With growing awareness around environmental concerns, there is a rising demand for sustainable and recyclable ESD packaging solutions. Manufacturers are increasingly investing in biodegradable or recyclable materials for ESD packaging to reduce environmental impact and meet sustainability goals.

Invest in Our Premium Strategic Solution: https://www.towardspackaging.com/price/5364

Get the latest insights on packaging industry segmentation with our Annual Membership – https://www.towardspackaging.com/get-an-annual-membership

If you have any questions, please feel free to contact us at sales@towardspackaging.com

Browse our Brand-New Journal:

https://www.towardshealthcare.com

https://www.towardsautomotive.com

For Latest Update Follow Us: https://www.linkedin.com/company/towards-packaging/

Get Our Freshly Printed Chronicle: https://www.packagingwebwire.com/