Table of Contents

TogglePackaging Inspection Systems Market Outlook Growth from 2025 to 2034

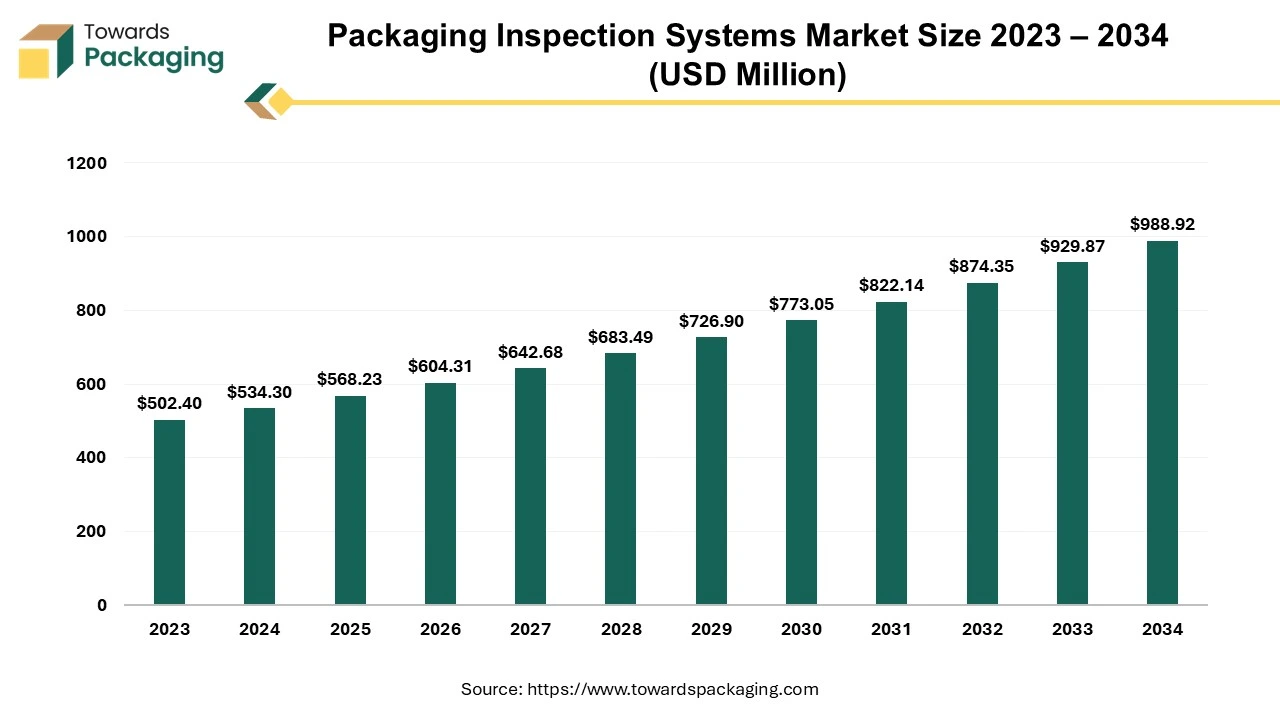

The global market for packaging inspection systems was valued at approximately US$ 534.30 million in 2024 and is expected to grow to about US$ 988.92 million by 2034. This growth represents a compound annual growth rate (CAGR) of 6.35% during the forecast period from 2025 to 2034.

Download Statistical Data: https://www.towardspackaging.com/download-statistics/5427

Key Insights of the Packaging Inspection Systems Market:

- North America led the packaging inspection systems market in 2024.

- The Asia Pacific region is expected to experience significant growth in the market during the forecast period.

- The bottles & cans segment held the largest market share in 2024.

- The food & beverages sector was the dominant end-use segment in the packaging inspection systems market in 2024.

Packaging Inspection Systems: Ensuring Quality and Safety

Packaging inspection systems are automated tools used to check the quality, safety, and integrity of packaging materials and products during production. These systems use advanced technologies like machine vision, X-rays, sensors, and lasers to detect defects in packaged goods, making sure they meet the required standards. They are used across various industries, including food and beverages, pharmaceuticals, cosmetics, and consumer goods.

By testing packaging, companies can ensure their products are protected during transport and distribution, reducing the risk of damage. Packaging testing can also help lower costs by identifying the right level of protection needed and reducing the amount of packaging material used.

Key Functions of Packaging Inspection Systems:

- Detecting cracks, leaks, dents, or contamination in containers, bottles, cans, trays, or flexible packaging.

- Ensuring products are filled to the correct level to avoid underfilling or overfilling.

- Verifying that seals, caps, lids, and closures are intact to maintain product freshness and safety.

- Checking that labels, barcodes, and printed information are accurate and properly placed.

- Identifying foreign particles or contaminants inside packages using advanced imaging technologies like X-rays.

- Assessing the overall shape, size, and alignment of packages to detect any deformations or misalignments.

Packaging inspection systems are essential for maintaining product quality, ensuring regulatory compliance, and improving production efficiency, all while reducing waste and enhancing customer satisfaction.

Market Trends:

- Adoption of AI and Machine Learning: AI-powered systems can analyze vast amounts of data to detect defects with greater accuracy. Machine learning allows these systems to learn from new data, improving their ability to detect defects in various packaging formats and materials.

- Smart Vision Systems Integration: High-resolution cameras and machine vision systems are becoming more advanced, enabling real-time inspection of packaging at high speeds. These systems are used to detect issues like label misalignment, fill-level errors, and sealing problems.

- IoT and Industry 4.0: The integration of packaging inspection systems with IoT allows for real-time monitoring and data collection. This integration helps optimize production efficiency, reduce downtime, and enable predictive maintenance.

- VR and AR for Training: Virtual and augmented reality are being used to train operators on complex inspection systems, providing a hands-on experience without disrupting production.

- Flexible Packaging Inspection: With the rise of flexible packaging, new inspection systems are being developed to detect defects in non-rigid materials like pouches and sachets, ensuring their quality and integrity.

- Multi-Sensor Systems: Combining multiple technologies such as machine vision, lasers, X-rays, and infrared sensors into a single system provides a comprehensive approach to detecting both internal and external defects.

- Serialization and Traceability: Packaging inspection systems are increasingly being equipped with serialization and track-and-trace capabilities, ensuring product safety and regulatory compliance across the supply chain.

- SaaS and Cloud-Based Models: Cloud-based packaging inspection systems with Software-as-a-Service (SaaS) models offer flexibility for smaller manufacturers, allowing them to adopt advanced technologies without heavy initial investments. These models improve operational efficiency by enabling remote monitoring and data analysis.

How AI Improves Packaging Inspection:

AI enhances packaging inspection systems by detecting subtle defects, such as scratches, misprints, leaks, or irregular seals, that traditional systems or human inspectors might miss. Machine learning algorithms enable these systems to learn and adapt over time, improving defect detection as new data is processed.

AI systems can analyze packaging lines in real-time, identifying issues instantly and enabling immediate corrective actions. This reduces production delays, minimizes material waste, and improves overall efficiency. Additionally, AI can automate visual inspections, eliminating the need for human intervention, reducing labor costs, and increasing throughput.

Robots equipped with AI vision systems can handle high-speed inspection processes more effectively than humans. Deep learning models analyze large datasets of packaging images, detecting patterns and anomalies with high precision, ensuring that packaging meets quality standards and identifying errors such as label misalignment or unreadable barcodes.

Buy Premium Global Insight: https://www.towardspackaging.com/price/5427

Get the latest insights on packaging industry segmentation with our Annual Membership – https://www.towardspackaging.com/get-an-annual-membership

If you have any questions, please feel free to contact us at sales@towardspackaging.com

Browse our Brand-New Journal:

https://www.towardshealthcare.com

https://www.towardsautomotive.com

For Latest Update Follow Us: https://www.linkedin.com/company/towards-packaging/

Get Our Freshly Printed Chronicle: https://www.packagingwebwire.com/