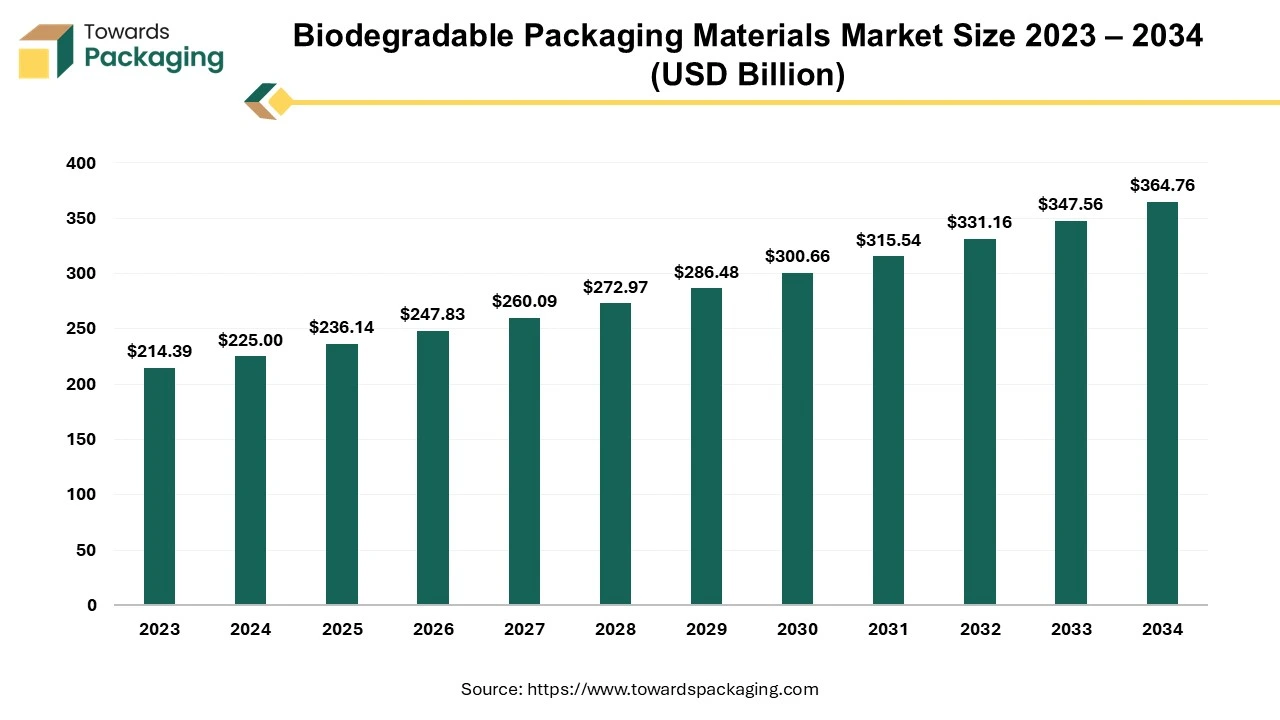

The global biodegradable packaging materials market, valued at US$ 225 billion in 2024, is projected to grow to US$ 364.76 billion by 2034, with a CAGR of 4.95%. The integration of AI and technology will drive this growth.

Download Statistical Data: https://www.towardspackaging.com/download-statistics/5392

Biodegradable packaging materials, made from natural resources, offer significant environmental benefits. These materials are sourced from renewable resources like plants and microorganisms, helping to reduce plastic waste that harms oceans and landfills. Since biodegradable packaging breaks down naturally, it plays a key role in lowering pollution. Additionally, it supports sustainability by reducing carbon emissions and promoting recycling and repurposing.

The decomposition process of biodegradable materials is driven by microorganisms such as bacteria, fungi, and algae, which break down the materials into water, carbon dioxide, and biomass. This helps conserve resources and supports a circular economy, further fueling market growth. The demand for biodegradable packaging is rising across various industries, including food and beverages, pharmaceuticals, and consumer goods.

Market Trends:

- Hemp Pulp Packaging: Made from hemp strains, hemp pulp has a higher cellulose content and grows faster than trees. It uses a sulfur-free process, offering a more sustainable solution for packaging.

- Mushroom Packaging: Created from mycelium (the root structure of mushrooms), it is customizable, offering water resistance, biodegradability, and thermal insulation. Its rapid prototyping process ensures a perfect fit for specific products.

- Seaweed-Based Packaging: Made from fast-growing seaweed like kelp, this packaging is eco-friendly and customizable in thickness, transparency, and texture. Kelp helps purify water and absorbs CO2, enhancing its sustainability.

- High-Barrier Packaging: Ultra-thin alumina (aluminum oxide) layers are applied to cellulose materials like paper and cardboard, creating a double barrier that resists water, oxygen, and moisture while maintaining recyclability and biodegradability.

- Alterpacks Sustainable Containers: Made from upcycled food waste and spent grains, these home-compostable, leak-resistant, and microwave-compatible containers are FDA and SFA-certified. They help reduce landfill waste and provide a sustainable alternative to traditional packaging.

Buy Premium Global Insight: https://www.towardspackaging.com/price/5392

Get the latest insights on packaging industry segmentation with our Annual Membership – https://www.towardspackaging.com/get-an-annual-membership

If you have any questions, please feel free to contact us at sales@towardspackaging.com

Browse our Brand-New Journal:

https://www.towardshealthcare.com

https://www.towardsautomotive.com

For Latest Update Follow Us: https://www.linkedin.com/company/towards-packaging/

Get Our Freshly Printed Chronicle: https://www.packagingwebwire.com/