Fiber-Based Packaging Market Growth and Trends (2024-2034)

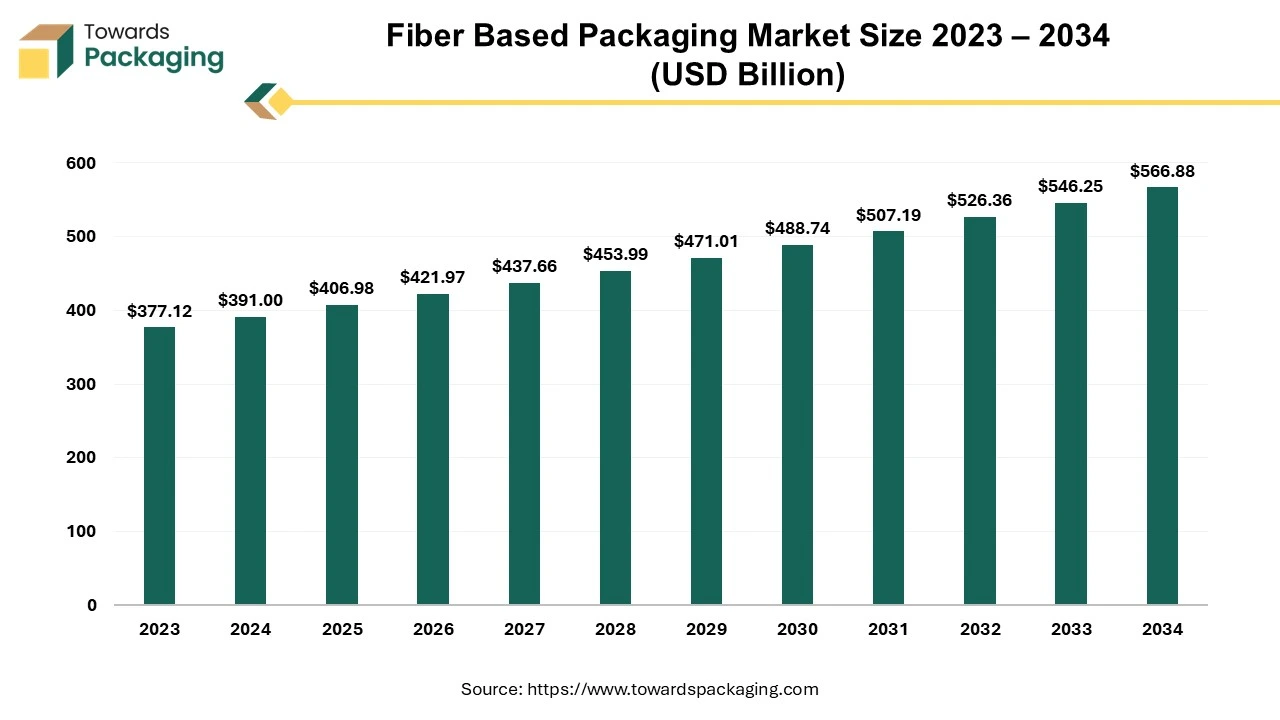

The global fiber-based packaging market was valued at $377.12 billion in 2023 and is expected to grow to approximately $566.88 billion by 2034. This growth is projected to occur at a compound annual growth rate (CAGR) of 3.85% from 2024 to 2034.

Download Statistical Data: https://www.towardspackaging.com/download-statistics/5384

Key players in the fiber-based packaging market are focusing on inorganic growth strategies, such as mergers and acquisitions, to develop advanced technologies for manufacturing fiber-based packaging. This is expected to drive the market’s growth during the forecast period.

Key Insights of the Fiber-Based Packaging Market:

- North America led the fiber-based packaging market in 2023.

- The Asia Pacific region is projected to experience significant growth during the forecast period.

- The corrugated segment was the market leader by material type in 2023.

- Recycled fiber was the dominant material source in the market in 2023.

- The corrugated box segment is expected to see substantial growth during the forecast period.

- The food and beverages sector was the largest end user of fiber-based packaging in 2023.

Fiber-Based Packaging: A Sustainable Alternative

Fiber-based packaging includes materials like cardboard, paper, and other plant-based substances, which are often sourced from agricultural waste or wood pulp. Unlike synthetic or plastic packaging, fiber-based packaging is more eco-friendly. It is made from renewable resources like trees and agricultural byproducts. Unlike plastic, which takes hundreds of years to break down, fiber-based packaging decomposes much faster when exposed to natural elements, reducing its environmental impact. Additionally, many fiber-based materials, especially paper and cardboard, are highly recyclable, allowing them to be reused multiple times, which helps minimize waste and reliance on new raw materials. As more consumers seek eco-friendly options, fiber-based packaging is becoming an increasingly popular choice for brands aiming to attract environmentally conscious customers.

How AI Can Enhance the Fiber-Based Packaging Industry

AI has the potential to greatly improve the fiber-based packaging industry by boosting sustainability, innovation, and efficiency. Here are some key ways AI can make a difference:

- Optimizing Packaging Designs: AI can help create more efficient packaging designs, reducing material waste while improving strength-to-weight ratios. Machine learning algorithms can analyze material usage and suggest ways to cut down on excess material while still maintaining the packaging’s durability.

- Improving Quality Control: AI-powered computer vision systems can be used for real-time quality control during production. These systems can detect defects in printing, raw materials, or finished products, helping to maintain consistent quality and reduce waste caused by human error or equipment issues.

- Optimizing Supply Chain: AI can enhance supply chain management by predicting demand patterns, managing inventory, and streamlining material procurement. This can lower lead times and costs. AI can also improve logistics by optimizing shipping routes and tracking deliveries in real-time.

- Fostering Material Innovation: AI aids researchers in developing new sustainable materials or combinations of fibers that are lighter, stronger, or more biodegradable. By simulating different material properties and testing various formulations virtually, AI can speed up the innovation process.

- Minimizing Waste During Production: AI can help monitor and minimize waste in the manufacturing process by optimizing production schedules and identifying areas where materials are used inefficiently. It can also track the entire lifecycle of packaging, ensuring designs are recyclable or reusable and helping companies measure their environmental impact.

- Understanding Consumer Preferences: AI can analyze market trends and consumer preferences, allowing companies to tailor their packaging to meet the demand for aesthetics, functionality, and sustainability. This data helps brands select the right fibers or designs that resonate with environmentally conscious consumers.

- Driving Automation: AI-driven robotics can automate tasks such as cutting, folding, and assembling packaging with precision. This boosts production efficiency while reducing labor costs and human error.

- Predicting Equipment Maintenance: AI can predict when equipment might fail or need maintenance, reducing downtime and ensuring smooth manufacturing operations. By using sensors and data analysis, AI helps prevent costly breakdowns and extends the lifespan of machinery.

Buy Premium Global Insight: https://www.towardspackaging.com/price/5384

Get the latest insights on packaging industry segmentation with our Annual Membership – https://www.towardspackaging.com/get-an-annual-membership

If you have any questions, please feel free to contact us at sales@towardspackaging.com

Browse our Brand-New Journal:

https://www.towardshealthcare.com

https://www.towardsautomotive.com

For Latest Update Follow Us: https://www.linkedin.com/company/towards-packaging/

Get Our Freshly Printed Chronicle: https://www.packagingwebwire.com/