Chemical Packaging Coding Equipment Market Growth

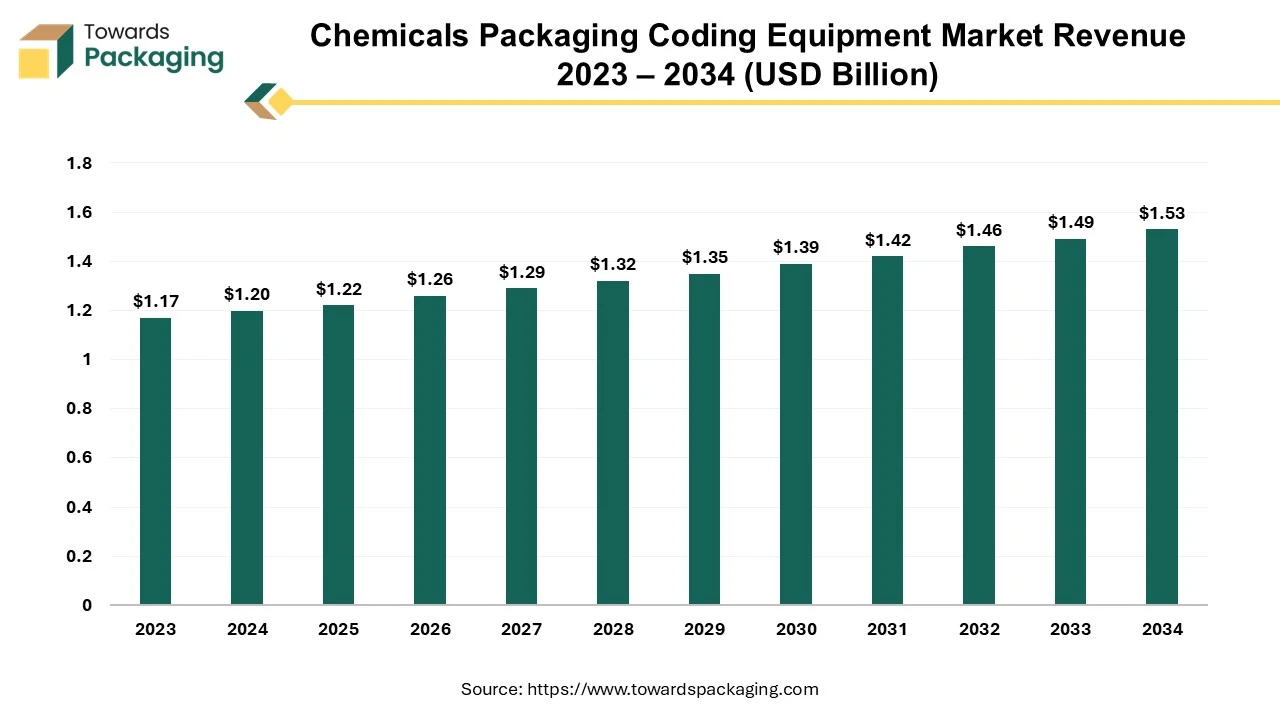

The global chemical packaging coding equipment market is expected to grow from USD 1.170 billion in 2023 to USD 1.536 billion by 2034, at a CAGR of 2.5% (2024–2034).

Download Statistical Data: https://www.towardspackaging.com/download-statistics/5372

The chemicals packaging coding equipment market is likely to register impressive growth during the projected forecast period. Due to the wide range of substrates, severe conditions, high throughput needs, chemical resistance, date marking requirements, batch coding, variable information and interaction with the production lines; coding and marking in the chemicals sector presents special challenges. Choosing the right coding and marking technologies like laser marking, inkjet printing, hi-resolution coding printers and labeling systems is important for overcoming these obstacles. Continuous maintenance as well as the support is also necessary to guarantee peak performance and adherence to industry standards. Complete attention must be paid to every part of the production process, from guaranteeing regulatory compliance to upholding brand integrity.

The stringent regulatory requirements along with the increased demand for the chemical products across various industries are expected to augment the growth of the chemicals packaging coding equipment market during the forecast period. Furthermore, the growing concerns over product traceability and safety as well as the expansion of the specialty chemicals sector are also anticipated to augment the growth of the market. Additionally, the technological advancements in the coding equipment along with the surge in the e-commerce has amplified the need for clear and traceable product information on the chemical packages is also projected to contribute to the growth of the market in the near future.

Key Trends and Insights

- Smart Coding Technologies on the Rise

Innovative solutions like self-verifying codes, interleaved marking, dynamically changing fonts, and verifiable codes are gaining traction. Self-verifying codes follow specific rules, such as digits being multiples of one another or summing to a set number, ensuring accuracy. Dynamically changeable fonts, generated by software, create unique product codes and help prevent downtime by identifying potential equipment issues before they occur. - Advances in Marking Speed and Quality

Manufacturers are continuously improving marking efficiency, speed, and precision. High-speed scanning systems, a major breakthrough in laser marking, enable faster marking without compromising accuracy by utilizing galvanometer mirrors to control the laser beam. This innovation boosts production rates and reduces turnaround times, particularly in packaging. - Revolutionary Developments in Digital Printing

The integration of 2D symbols through technologies like Thermal Transfer Overprinting (TTO) and laser marking is transformative, with autocoding leading the charge. Autocoding automates code generation, ensures compliance with GS1 standards, and streamlines data management, enhancing operational efficiency. - Enhanced Print Quality with CIJ Printing

Continuous inkjet (CIJ) printing is evolving to meet the demand for superior print quality. Future CIJ printers will likely combine advanced imaging technologies and improved ink formulations to deliver sharper, more vibrant prints. As resolution improves, even the finest details can be reproduced with unmatched precision. - Regional Highlights

- North America: Held a significant market share in 2023, driven by stringent chemical labeling regulations and widespread automation in industrial packaging.

- Asia-Pacific: Poised to grow at the fastest rate, fueled by rapid industrialization and increasing chemical demand across sectors like agriculture, consumer goods, and construction.

Recent Innovations by Leading Market Players

- Videojet Technologies (November 2024)

Videojet Technologies announced exciting updates to its Videojet 2380 wide character marking system, first introduced earlier in the year. Designed for secondary packaging like cartons and cases, the Videojet 2380 can print 2D codes, high-resolution text, and product identifiers directly onto boxes. This feature reduces reliance on pre-printed packaging, cutting costs, storage needs, and waste. It also enables quick changes to print content, making it easier to adapt to shifting market demands. - InkJet, Inc. (June 2024)

InkJet, Inc. unveiled the ANSER Smart Printhead, a compact, high-resolution inkjet printer designed for seamless integration into automated production lines. Featuring the world’s smallest controller, this printer is ideal for operations with limited space. Its innovative replaceable printhead technology supports a variety of ink types, enabling precise coding on diverse substrates, further boosting its versatility and appeal.

Buy Premium Global Insight: https://www.towardspackaging.com/price/5372

Get the latest insights on packaging industry segmentation with our Annual Membership – https://www.towardspackaging.com/get-an-annual-membership

If you have any questions, please feel free to contact us at sales@towardspackaging.com

Browse our Brand-New Journal:

https://www.towardshealthcare.com

https://www.towardsautomotive.com

For Latest Update Follow Us: https://www.linkedin.com/company/towards-packaging/

Get Our Freshly Printed Chronicle: https://www.packagingwebwire.com/