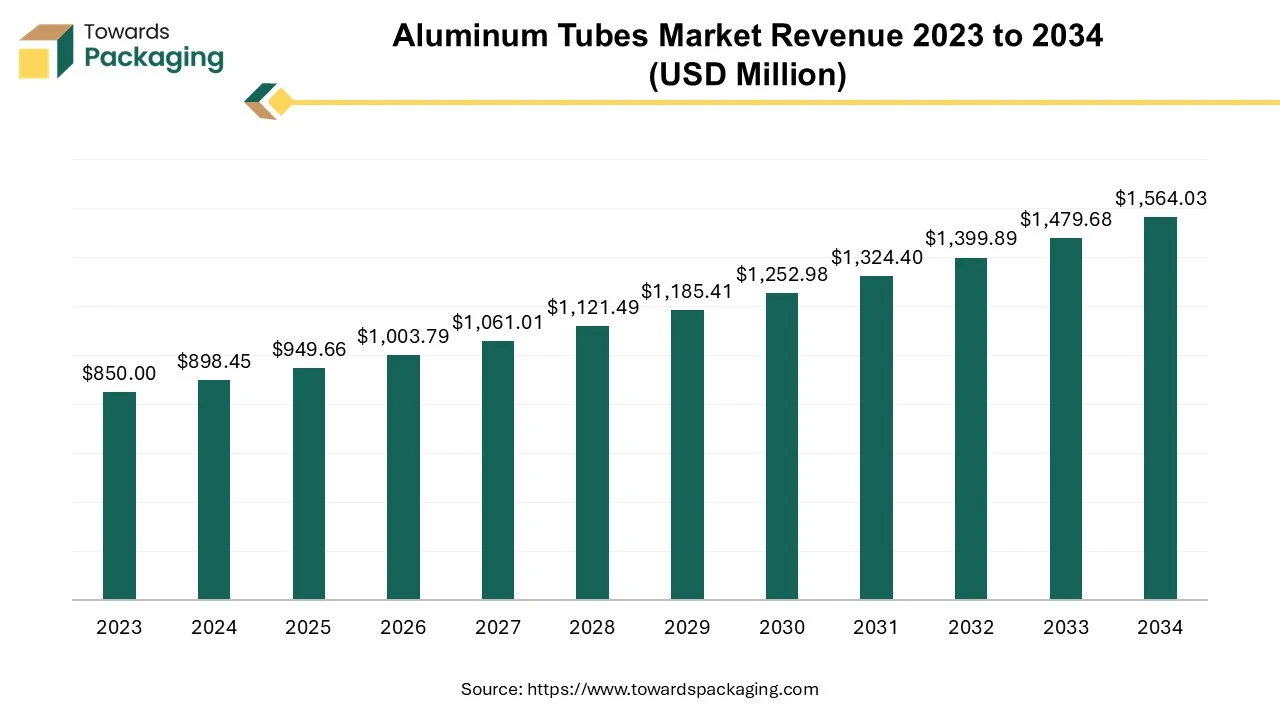

The global aluminum tubes market was valued at US$ 850 million in 2023 and is expected to grow to approximately US$ 1,564.03 million by 2034, with a compound annual growth rate (CAGR) of 5.7% from 2024 to 2033.

Download Statistical Data: https://www.towardspackaging.com/download-statistics/5289

The key players operating in the market are focused on adopting inorganic growth strategies like acquisition and merger to develop advance technology for manufacturing aluminum tubes which is estimated to drive the global aluminum tubes market over the forecast period.

Major Key Insights of the Aluminum Tubes Market

- Europe dominated the aluminum tubes market in 2023.

- By tuber type, the squeeze tube segment dominated the market with the largest share in 2023.

- By product, stand-up cap segment is expected to grow at significant rate during the forecast period.

- By capacity, 50 to 100 ml segment registered its dominance over the global market in 2023.

- By end user, the Cosmetics and Personal Care segment dominated the aluminum tubes market in 2023.

Aluminum Tubes Market: A Sustainable Packaging Solution

Aluminum tubes have become a go-to choice for eco-friendly packaging across a wide range of products, from lotions and gels to effervescent tablets. Known for their versatility, aluminum tubes are especially popular in the personal care and pharmaceutical industries, offering a winning combination of product protection, durability, and aesthetic appeal. These tubes not only preserve the quality of the contents but also support sustainability efforts, making them a favored option in today’s environmentally conscious market. As demand grows, innovations in aluminum tube design and manufacturing are set to further enhance their role across these sectors.

One of the standout features of aluminum tubes is their ability to be customized with high-quality graphics, vibrant colors, and brand logos, making products more appealing to consumers. In addition to their visual appeal, aluminum is a highly recyclable material, which helps meet the increasing demand for sustainable packaging solutions. Whether used in personal care, pharmaceuticals, or food packaging, aluminum tubes offer an effective, eco-friendly, and versatile solution for a variety of products.

The durability, superior barrier properties, and recyclability of aluminum tubes make them an ideal choice for brands aiming to extend product shelf life while appealing to consumers who prioritize sustainability. As industries evolve, aluminum tubes are poised to play an even larger role in shaping the future of innovative, sustainable packaging strategies. The global packaging market is projected to grow from USD 1.20 trillion in 2022 to USD 1.58 trillion by 2032, at a steady CAGR of 3.16% between 2023 and 2032.

Top 5 Factors Driving Aluminum Tubes Market Growth

- The expansion of global markets and the launch of food brands in new countries have significantly boosted the demand for aluminum tubes, driving market growth in the near term.

- A growing focus on cost reduction and improving production efficiency is expected to further fuel the growth of the specialty aluminum tube market.

- Emerging trends and new applications for aluminum tubes in various industries are anticipated to drive the market’s expansion throughout the forecast period.

- Increased regulatory support for sustainable packaging solutions is expected to further stimulate market growth.

- The adoption of advanced technologies in aluminum tube production is expected to accelerate market growth in the coming years.

How AI Can Transform the Aluminum Tubes Industry

Artificial Intelligence (AI) has the potential to revolutionize the aluminum tubes market in several impactful ways. By optimizing manufacturing processes, enhancing predictive maintenance, and supporting sustainability efforts, AI can improve both efficiency and quality in tube production.

AI can monitor machinery data to predict potential failures, enabling timely maintenance that reduces downtime and boosts production efficiency. Machine learning algorithms can optimize key processes such as extrusion and printing, minimizing waste and ensuring consistent, high-quality output.

AI-powered vision systems can also inspect aluminum tubes in real-time for defects, ensuring the highest quality standards are met without the need for manual inspection. Additionally, AI can analyze production data to spot trends and anomalies, allowing manufacturers to proactively adjust processes and improve outcomes. By studying market trends and consumer behavior, AI can help manufacturers predict demand and optimize inventory levels, reducing excess stock and improving supply chain efficiency.

Buy Premium Global Insight: https://www.towardspackaging.com/price/5289

Get the latest insights on packaging industry segmentation with our Annual Membership – https://www.towardspackaging.com/get-an-annual-membership

If you have any questions, please feel free to contact us at sales@towardspackaging.com

About Us

Towards Packaging is a leading global consulting firm specializing in providing comprehensive and strategic research solutions. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations. We stay abreast of the latest industry trends and emerging markets to provide our clients with an unrivalled understanding of their respective sectors. We adhere to rigorous research methodologies, combining primary and secondary research to ensure accuracy and reliability. Our data-driven approach and advanced analytics enable us to unearth actionable insights and make informed recommendations. We are committed to delivering excellence in all our endeavours. Our dedication to quality and continuous improvement has earned us the trust and loyalty of clients worldwide.

Browse our Brand-New Journal:

https://www.towardshealthcare.com

https://www.towardsautomotive.com

For Latest Update Follow Us: https://www.linkedin.com/company/towards-packaging/

Get Our Freshly Printed Chronicle: https://www.packagingwebwire.com/