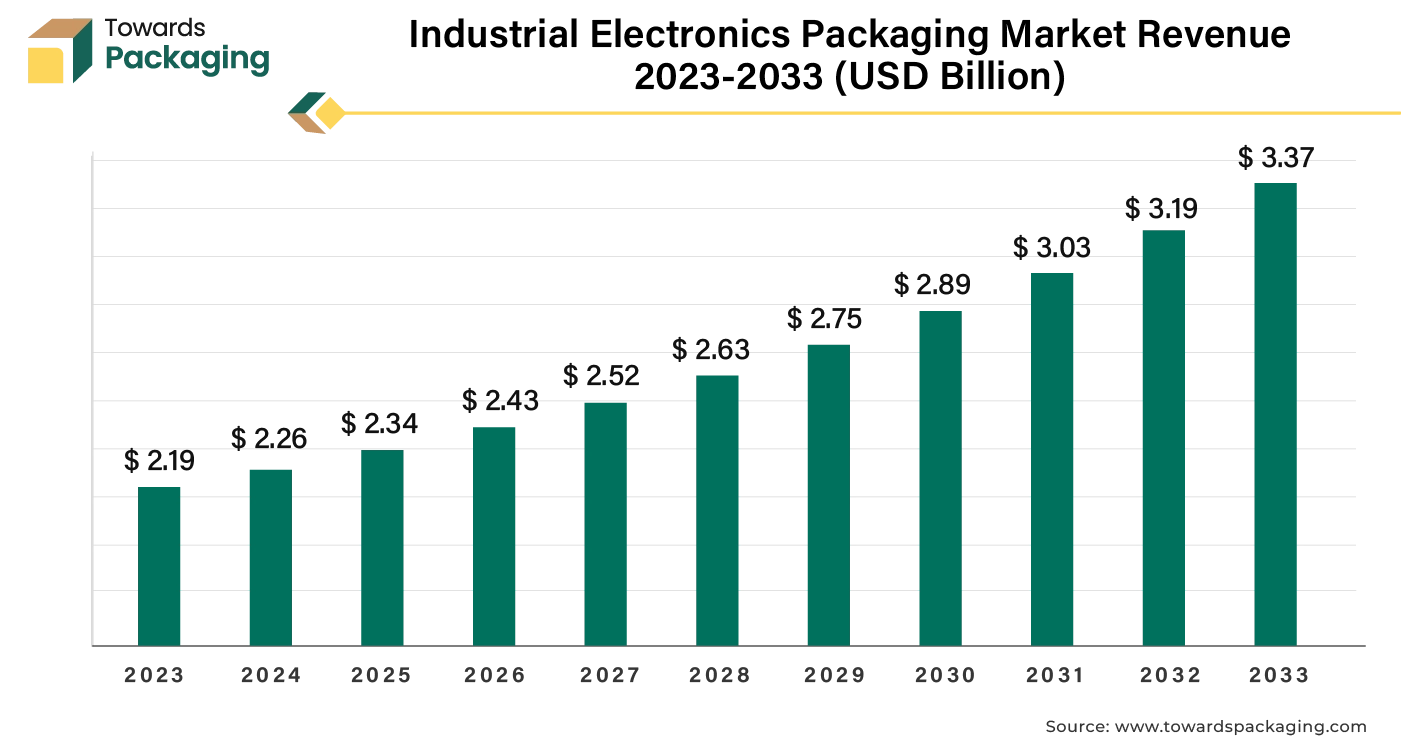

The global industrial electronics packaging market size is estimated to reach USD 3.37 billion by 2033, up from USD 2.19 billion in 2023, at a compound annual growth rate (CAGR) of 4.54% from 2024 to 2033.

Download Statistical Data: https://www.towardspackaging.com/download-statistics/5238

The industrial electronics packaging market is anticipated to augment with a considerable CAGR during the forecast period. Industrial electronics packaging deals with the packaging of components such as the sensors, meters, AC/DC drives, resistors and semiconductors, among others that are important in human-machine interfaces (HMIs), programmable logic controllers (PLCs) as well as the industrial robots. Package types can vary from basic plastic housings to specialist glass-to-metal or ceramic packing. Numerous aspects influence the packaging decision, such as the size and type of the component, the application, heat dissipation needs, electrical properties as well as the manufacturing method.

The rise of industrial automation and smart manufacturing coupled with the expansion of industrial sectors such as the automotive, energy and telecommunications is anticipated to augment the growth of the industrial electronics packaging market within the estimated timeframe. The advancement in technology, particularly in the field of electronics along with innovations in packaging materials like the development of advanced composites and anti-static films are also expected to support the market growth.

Furthermore, the integration of smart technologies into packaging, including IoT capabilities for real-time monitoring as well as the emerging markets in Asia-Pacific, Latin America, and Africa present significant opportunities for growth due to increasing industrialization and technological adoption is also likely to contribute to the growth of the market in the years to come. The global packaging market size is estimated to grow from USD 1.20 trillion in 2022 to reach an estimated USD 1.58 trillion by 2032, growing at a 3.16% CAGR between 2023 and 2032.

Industrial Electronics Packaging Market Key Trends and Findings

- To fulfill the ever-increasing needs of contemporary electronic packaging applications, it is imperative to develop innovative materials with specialized features. Due to its electrical insulation, thermal stability and flexibility, silicone rubber (SR) composites have drawn a lot of attention since they are perfect for electronic equipment.

- To contribute to the development of the upcoming generation of extremely fast electronic chips, researchers are working on an organic material that is more potent, flexible and thin. Compared to the modern electrical circuits, the material utilizes light or photons that travel at a far faster speed. Since the super transport of excitons is composed just of carbon and hydrogen, devices might be readily recyclable or biodegradable, avoiding the tons of e-waste that are currently produced by the devices.

- The core technology of present-day and future mobility solutions is microelectronic systems and the packaging technology that goes along with them. Growing performance and lifetime requirements coupled with the electronic system downsizing need the creation of new, dependable materials, advancements in assembly and interconnection processes and expansion of the current analytical and testing methodologies.

- North America held largest market share of 36.15% in 2023. This is owing to the advanced industrial automation, high technological adoption and the stringent regulatory standards in the region.

- Asia-Pacific region is expected to grow at a CAGR of 6.49% during the forecast period due to the rapid industrial growth and technological advancement as well as the significant investments in the infrastructure.

Industrial Electronics Packaging Market Drivers

Rise of Industrial Automation and Smart Manufacturing

The rise of industrial automation and smart manufacturing is expected to augment the growth of the industrial electronics packaging market during the forecast period. Industrial automation significantly improves the productivity of jobs, processes, and the enterprises with plants and on shop floors. A fraction of the working force is now required for processes that historically required armies of workers. The digital transformation of manufacturing, in particular the introduction of the Industrial Internet of Things, results in greater throughput and reduced downtime as machinery is more efficiently engaged and maintained. It is predicted that the use of sensors in machinery results in a 10% to 15% reduction in maintenance expenses. Digital automation solutions also reduce the environmental impact since the new plants control production, resources, and business operations in an eco-efficient approach by monitoring the property and operational details across numerous sites and the value chains.

Furthermore, smart factory usage is becoming more and more popular across the industries. Many businesses are aware of the potential advantages of adopting the Industry 4.0 technology, which include higher productivity, lower prices and better quality. A prime illustration of this is Mitsubishi Electric. Their prototype factory in Thailand, developed in partnership with True 5G and LERTVILAI, has autonomous mobile robots, VR and AR to improve production line performance, as well as fast data processing and examination of the production lines. Reliability as well as the effectiveness in packaging becomes important as manufacturing technologies and automated systems are used by businesses at an increasing rate.

Smart manufacturing and automation sometimes require complicated electronic systems that must perform properly in the challenging circumstances. Packaging needs to offer strong defense against the environmental elements including moisture, dust, and temperature changes, as well as against physical impacts to guarantee the longevity and functionality of these systems.

Industrial Electronics Packaging Market Restraints

Various Complexities in Packaging

The numerous challenges in the packaging options are likely to hinder the growth of the industrial electronics packaging market within the estimated timeframe. Future packaging solutions will need to satisfy the 5% cost/pin reduction target annually while being far more complicated than those made possible by the existing technologies. The scaling zone array chip-to-package interconnect offers the number of input/output ports required for the tiny chip sizes required by handheld devices. It also delivers the current to the chip’s interior and provides a large I/O count that is required by high-performance and the cost-performance products at a chip size that is reasonable.

For high-frequency applications, package designers have to deal with a number of obstacles such as the interconnects’ inductance, the impedance of the communication lines on the packages, cross-talk interference between these lines and the positioning of decoupling capacitances on the PCB, in the package as well on the chip.

Furthermore, each electronic component may require specialized protection due to its size, shape and the environmental conditions it may face such as the temperature extremes, dampness, or the physical impacts. Precise customization is necessary, which complicates the design and manufacturing processes and frequently calls for cooperation between the manufacturers, engineers and designers to guarantee the peak performance.

Another significant difficulty is managing thermals for the growing future chip power in a system’s constrained space. In order to meet these challenges, a large amount of research and development effort will need to be put into studying the thermal behavior, mechanics as well as the electrical efficiency of the newly developed materials in addition to the software tools needed to build and model these novel structures.

Industrial Electronics Packaging Market Opportunities

Growing Electronics Industry

The growing electronics industry particularly in the emerging economies is expected to create a substantial opportunity for the growth of the industrial electronics packaging market in the years to come. The main factors driving the demand are the growing need for advanced semiconductors, especially from new sectors like electric vehicles (EV) and artificial intelligence (AI), as well as the acceleration of digitalization and industrial automation. The electronics sector is a creative, technologically advanced sector. Specifically, the semiconductor industry adds a great deal of value and offers manufacturers strong profit margins. Furthermore, a strategic goal for the US, EU, and Asia is the growing manufacturing of semiconductors. Recently, laws have been introduced to encourage the expansion of domestic manufacturing in each of the three regions.

Additionally, electronic components are becoming more and more in demand as smart factories, digital supply networks and the hyper-connected supply chains expand as they help in increasing the productivity up to 12%. While there are limitations to some aspects of the manufacturing, the integration of AI is helping to eliminate these limitations and many businesses are starting to realize the advantages of using the AI solutions. For example, AI Process Optimization facilitates the quality monitoring by assisting in the identification as well as removal of the faulty products before they waste more resources, time and energy.

Artificial Intelligence is expected to have a more significant role in the electronics manufacturing sector than it has in the past. As a result, the market for the industrial electronics packaging is expected to grow significantly due to the electronics industry’s growth, which is being fueled by the emerging economies, digitalization as well as the increased semiconductor production. These developments require creative packaging solutions that are designed as per the changing technological needs and growing production capacities.

Buy Premium Global Insight: https://www.towardspackaging.com/price/5238

Get the latest insights on packaging industry segmentation with our Annual Membership – https://www.towardspackaging.com/get-an-annual-membership

If you have any questions, please feel free to contact us at sales@towardspackaging.com

About Us

Towards Packaging is a leading global consulting firm specializing in providing comprehensive and strategic research solutions. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations. We stay abreast of the latest industry trends and emerging markets to provide our clients with an unrivalled understanding of their respective sectors. We adhere to rigorous research methodologies, combining primary and secondary research to ensure accuracy and reliability. Our data-driven approach and advanced analytics enable us to unearth actionable insights and make informed recommendations. We are committed to delivering excellence in all our endeavours. Our dedication to quality and continuous improvement has earned us the trust and loyalty of clients worldwide.

Browse our Brand-New Journal:

https://www.towardshealthcare.com

https://www.towardsautomotive.com

For Latest Update Follow Us: https://www.linkedin.com/company/towards-packaging/

Get Our Freshly Printed Chronicle: https://www.packagingwebwire.com/