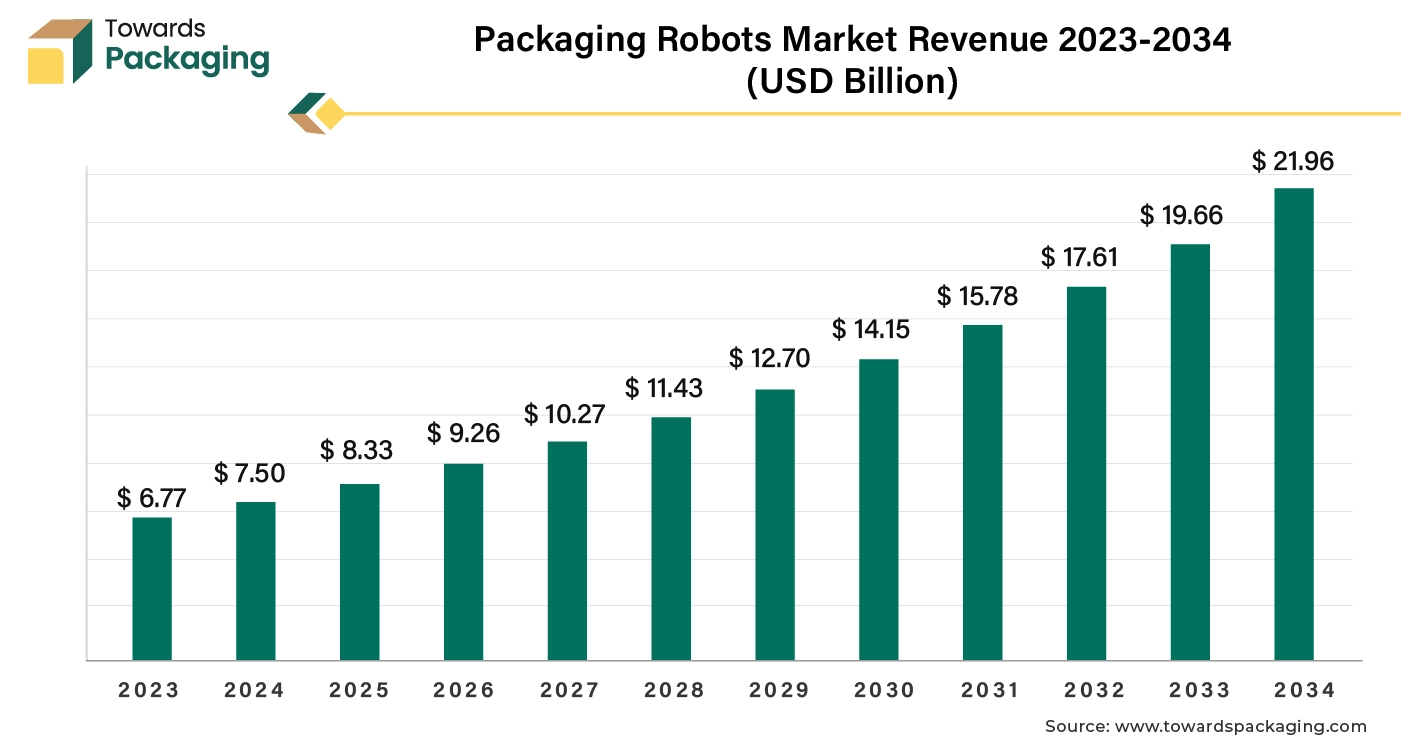

The global packaging robots market is on a robust growth trajectory, with its size reaching US$ 6.77 billion in 2023. Projections show that the market will expand further to an impressive US$ 21.96 billion by 2034, growing at a CAGR of 11% from 2024 to 2033. This surge is driven by the increasing adoption of automation across various sectors, enhancing the efficiency of packaging processes.

Download Statistical Data: https://www.towardspackaging.com/download-statistics/5270

Overview of the Packaging Robots Market: 2023 – 2034

Packaging robots are automated systems designed to perform diverse tasks during the packaging process, offering industries enhanced speed, precision, and flexibility. The demand for these robots has surged due to their ability to reduce labor costs and eliminate human errors, which are critical in today’s fast-paced manufacturing environments. They can handle a wide range of products, making them versatile for industries such as food and beverage, pharmaceuticals, e-commerce, and logistics.

Key Insights for 2023:

- Asia Pacific led the market in 2023, dominating the packaging robot landscape with a significant market share.

- North America is expected to witness notable growth during the forecast period, driven by increasing investments in automation and technological advancements.

- By gripper type, the clamp and claws segment held the largest market share in 2023.

- The pick & place segment is forecasted to grow significantly by 2034.

- The food and beverage industry emerged as the leading end-user of packaging robots in 2023, highlighting its vast dependence on automated systems.

Automated Packaging: Revolutionizing Industries

Packaging robots have transformed traditional packaging methods, delivering speed, accuracy, and cost-effectiveness. These robots are used in various stages of packaging, such as sorting, palletizing, labeling, and wrapping. By automating these tasks, companies can streamline their operations and achieve higher productivity.

Types of Packaging Robots:

- Articulated Robots: Equipped with rotary joints, these robots can move across multiple axes, making them ideal for tasks such as palletizing, picking, and placing.

- Delta Robots: Known for their speed and precision, they excel in handling small, lightweight products.

- SCARA Robots: Designed for high-speed, accurate movements, often used in pick-and-place tasks.

- Collaborative Robots (Cobots): Cobots are designed to work alongside human operators, enhancing safety and flexibility.

- Mobile Robots: These robots can autonomously navigate factory floors, transporting goods between stations for packaging and storage.

Key Functions of Packaging Robots:

- Sorting: Products are sorted based on size, type, or other criteria to ensure efficient packaging.

- Filling: Robots fill containers with products, ensuring precision and speed.

- Sealing: Automated sealing ensures packaging is securely closed, reducing contamination risks.

- Labeling: Robots apply labels with accuracy, minimizing misprints or errors.

- Palletizing: Robots stack packaged products onto pallets, optimizing space and securing products for shipment.

- Wrapping: Packaging robots can wrap products with protective materials, ensuring safe transportation and storage.

Growth Drivers in the Packaging Robots Market

The rapid adoption of advanced technology and automation in the packaging industry is being fueled by several factors:

1. Cost Efficiency and Labor Savings

Robotic automation offers substantial cost-saving benefits. By reducing labor requirements and increasing production efficiency, companies can achieve long-term savings. This is particularly important in labor-intensive industries, where high turnover and increasing wages have driven companies to invest in robotic solutions.

2. Enhanced Productivity

Packaging robots can operate 24/7 with minimal downtime, allowing companies to meet growing demands without compromising on speed or accuracy. The ability to handle multiple products and packaging formats with precision ensures consistent output.

3. Safety and Reliability

In industries where safety and hygiene are critical, such as food processing and pharmaceuticals, robots play a crucial role. By minimizing human involvement, packaging robots significantly reduce contamination risks and enhance workplace safety.

4. Growing Demand in Emerging Markets

Countries in the Asia Pacific region, such as China, India, and Japan, have become key players in the packaging robots market. Increasing investments in automation technologies and the rising demand for packaged goods in these markets have bolstered growth. Furthermore, expanding manufacturing sectors and favorable government policies are driving the adoption of robotics across various industries.

5. Technological Advancements

Ongoing innovations in robotics technology are pushing the boundaries of what packaging robots can achieve. Advanced sensors, AI-driven systems, and real-time monitoring tools are enabling robots to perform complex tasks with greater precision and flexibility. This continuous evolution promises to further enhance the scalability and adaptability of robotic systems.

Major Players in the Packaging Robots Market

Several companies are spearheading the development of advanced packaging robots, focusing on innovations that meet the diverse needs of industries:

- ABB Ltd.: ABB is a global leader in industrial robotics, offering a range of packaging robots designed for high-speed, precision tasks.

- Fanuc Corporation: Specializing in automation and robotics, Fanuc offers a wide array of robots tailored for various packaging functions.

- KUKA AG: KUKA provides cutting-edge robotic solutions for the packaging industry, with a focus on automated palletizing and pick-and-place systems.

- Yaskawa Electric Corporation: Yaskawa is known for its advanced robotics technologies, offering versatile robots capable of handling complex packaging tasks.

- Universal Robots: A pioneer in collaborative robots, Universal Robots focuses on providing flexible solutions for packaging tasks that require close interaction with human workers.

These companies are leveraging strategic partnerships, mergers, and acquisitions to expand their global footprint and stay ahead in the competitive packaging robots market.

Future Outlook: Packaging Robots Market 2024 – 2034

As the global demand for automated packaging systems continues to rise, the packaging robots market is expected to witness unprecedented growth. By 2034, the market size is projected to reach nearly US$ 22 billion, with advancements in robotics technology playing a pivotal role in this expansion.

Key Trends to Watch:

- AI Integration: The integration of artificial intelligence (AI) in packaging robots will enhance decision-making and increase operational efficiency.

- Collaborative Robotics (Cobots): As cobots become more prevalent, they will drive the adoption of automation in small and medium enterprises (SMEs) that were previously unable to invest in expensive robotic systems.

- Customization: Packaging robots will become more adaptable to customized packaging needs, allowing manufacturers to cater to specific market demands.

The packaging robots market is set for explosive growth over the next decade. With advancements in automation technologies, cost-saving benefits, and rising demand from emerging markets, these robots will continue to transform the packaging industry.

Buy Premium Global Insight: https://www.towardspackaging.com/price/5270

Get the latest insights on packaging industry segmentation with our Annual Membership – https://www.towardspackaging.com/get-an-annual-membership

If you have any questions, please feel free to contact us at sales@towardspackaging.com

About Us

Towards Packaging is a leading global consulting firm specializing in providing comprehensive and strategic research solutions. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations. We stay abreast of the latest industry trends and emerging markets to provide our clients with an unrivalled understanding of their respective sectors. We adhere to rigorous research methodologies, combining primary and secondary research to ensure accuracy and reliability. Our data-driven approach and advanced analytics enable us to unearth actionable insights and make informed recommendations. We are committed to delivering excellence in all our endeavours. Our dedication to quality and continuous improvement has earned us the trust and loyalty of clients worldwide.

Browse our Brand-New Journal:

https://www.towardshealthcare.com

https://www.towardsautomotive.com

For Latest Update Follow Us: https://www.linkedin.com/company/towards-packaging/

Get Our Freshly Printed Chronicle: https://www.packagingwebwire.com/