The packaging supply chain is a critical component of global commerce, spanning from raw material sourcing to the delivery of finished packaged goods to consumers. As industries evolve and new challenges emerge, the packaging supply chain must adapt to ensure efficiency, sustainability, and resilience. This article explores the current trends shaping the packaging supply chain, identifies key challenges, and looks at future innovations set to transform the industry.

Key Trends in the Packaging Supply Chain

- Sustainability and Eco-Friendly Packaging Materials Sustainability is at the forefront of the packaging industry’s transformation. Companies are adopting eco-friendly materials to reduce environmental impact and meet growing consumer demand for sustainable practices. This includes the shift from single-use plastics to biodegradable, recyclable, and reusable packaging materials. Many businesses are also incorporating life cycle assessments to minimize the carbon footprint of their packaging supply chains.

- Digitization and Smart Packaging The integration of digital technologies into packaging is revolutionizing the supply chain. Smart packaging, equipped with sensors, RFID, and NFC technology, enables real-time tracking of products. This improves inventory management, reduces waste, and increases visibility across the supply chain. These technologies also help combat counterfeit products, ensuring authenticity and enhancing customer confidence.

- Circular Economy Initiatives As part of the drive towards sustainability, circular economy principles are gaining traction within the packaging supply chain. This approach focuses on minimizing waste and maximizing the reuse, recycling, and recovery of packaging materials. Companies are increasingly designing packaging with end-of-life considerations in mind, promoting closed-loop systems that extend the lifecycle of materials.

- Localization of Packaging Production To mitigate the risks associated with global supply chain disruptions—highlighted during the COVID-19 pandemic—many companies are shifting toward localized production. By manufacturing packaging materials closer to their markets, businesses can reduce lead times, transportation costs, and environmental impact. Localization also allows for greater flexibility and responsiveness to changes in consumer demand.

- Sourcing Raw Materials Responsibly Ethical sourcing is becoming an essential aspect of the packaging supply chain. Consumers and regulators alike are demanding transparency in where and how raw materials are sourced. Companies are increasingly committing to responsible procurement practices, ensuring that materials are sourced sustainably and under fair labor conditions. This shift is especially important for materials like paper, plastic, and metals that have significant environmental impacts.

Download White Paper: https://www.towardspackaging.com/personalized-scope/5066

Packaging in Supply Chain Management Market Size

At one-point, numerous businesses perceived packaging to fulfil two fundamental roles within supply chain management.

Packaging is vital in protecting products during transportation, ensuring that items reach their destination safely and without damage. This function is crucial in maintaining product quality and reducing potential losses or returns due to transportation mishaps.

Another essential function of packaging within supply chain management is optimizing space utilization on delivery vehicles. By efficiently arranging products within the packaging, companies can ensure that the correct quantity of items is shipped to distribution centers, fulfillment centers, retailers, and customers. This optimization helps reduce wasted space, leading to more efficient transportation and ultimately saving fuel and transportation costs. Businesses can enhance their logistical operations and improve overall supply chain efficiency by maximizing available space.

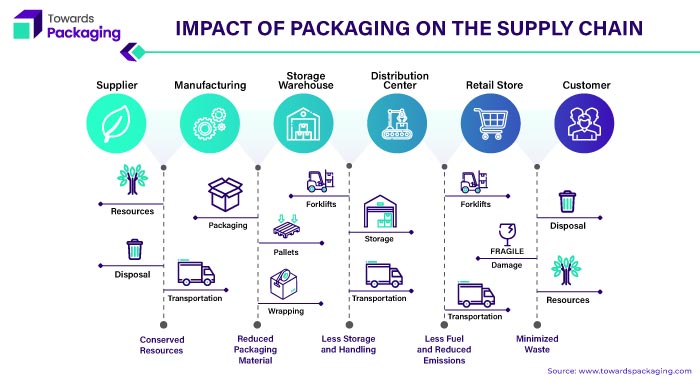

In the rapidly evolving landscape of modern business, cutting-edge technologies and innovative solutions have revolutionized packaging options across diverse industries such as aerospace, food, beverage, pet care, and paints & coatings. As a result, companies have gained valuable insights into the immense opportunities presented by packaging materials. The significance of packaging in the supply chain has transcended its traditional purpose, now encompassing critical aspects like environmental protection, product traceability, seamless item handling, efficient distribution, and the potential to boost marketing campaigns. These multifaceted factors can be classified into three primary packaging functions: flow optimization, marketing, and environmental sustainability.

Ensuring customers remember your product long after the purchase is of utmost significance to businesses striving to attract new customers and cultivate unwavering loyalty throughout their company’s lifespan. While marketing efforts towards existing customers, such as email campaigns and newsletters, are essential, packaging emerges as a potent tool for captivating and retaining customers, ultimately bolstering sales. The lasting impact of well-crafted packaging can leave a lasting impression on consumers, reinforcing brand recognition and fostering a positive perception of the product, thus encouraging repeat purchases and word-of-mouth recommendations. As a result, businesses must recognize the strategic value of packaging as a vital component in their customer engagement and retention strategies, enhancing the overall customer experience and ensuring sustained success in the market.

Packaging is crucial in creating a captivating visual appeal that can effectively attract customers to your products. Business owners widely recognize that a visually appealing item displayed on a shelf holds power to sway customers to choose it over competing options. While some may assume that custom packaging is the sole means of standing out on the shelf, the truth is that decoration can metamorphose any ordinary commodity packaging into a unique and eye-catching package. This principle also extends to packaging used in manufacturing processes. Instead of relying on plain, uniform brown cartons and boxes for shipping, opting for visually stunning packaging elevates the customer experience, leaving a lasting and memorable impression upon receipt.

Modern packaging designs have opened opportunities to incorporate mobile-friendly promotional functions like QR codes. These dynamic elements empower customers to explore more about complementary products, gain insights into the company, or unlock exclusive sales discounts for future purchases. By leveraging these innovative packaging features, businesses can enhance customer engagement and build stronger brand connections, ultimately fostering brand loyalty and long-term success in the market.

Another crucial function of packaging in the supply chain is the “flow” aspect, which revolves around how packaging facilitates the movement of items throughout distribution and logistics processes. The flow function finds application in various stages, such as the movement of raw materials to workstations, the use of packaging for logistical strategies, efficient handling of packages within warehouse management systems, product distribution, customer unpacking, managing product returns, and even handling inventory disposal.

When considering the flow function, it becomes imperative for your packaging to ensure that raw materials or products seamlessly reach their intended destinations, be it internal production lines, warehouses, or customers. In some cases, the material composition of the packaging becomes a critical factor, especially when dealing with hazardous materials that require specific UN-rated packaging to meet shipping regulations.

Achieving smooth material flow can become challenging due to the many components and factors that must be considered. Therefore, gaining greater visibility into supply chain operations can drive the need for packaging redesigns to enhance traceability and safety measures throughout the process. By optimizing packaging for efficient flow, businesses can streamline their supply chain operations, minimize disruptions, and ultimately contribute to a more effective and sustainable distribution system.

Get the latest insights on packaging industry segmentation with our Annual Membership – https://www.towardspackaging.com/get-an-annual-membership

Challenges in the Packaging Supply Chain

- Rising Material Costs One of the biggest challenges for the packaging supply chain is the rising cost of raw materials. Fluctuations in the prices of key materials, such as plastics and paper, can significantly affect the profitability of packaging manufacturers. Additionally, as more companies transition to sustainable materials, demand for bioplastics and recycled materials is driving up costs.

- Supply Chain Disruptions Global events such as the COVID-19 pandemic and geopolitical tensions have exposed vulnerabilities in the packaging supply chain. Disruptions in transportation, labor shortages, and delays in raw material availability have caused bottlenecks. Companies must now build more resilient supply chains by diversifying suppliers, increasing safety stock, and investing in technology to mitigate these risks.

- Regulatory Compliance Packaging regulations vary widely across regions and are becoming more stringent, particularly around sustainability and waste reduction. Navigating these regulations while maintaining compliance adds complexity to the packaging supply chain. Companies must stay up to date with evolving regulations to avoid penalties and ensure their packaging meets local and global standards.

- Waste Management and Recycling Infrastructure Although many companies are adopting sustainable packaging materials, the infrastructure for recycling and waste management often lags behind. Inconsistent recycling capabilities across regions pose challenges in achieving a circular packaging supply chain. Building better waste management systems and increasing recycling rates are crucial for the industry’s future sustainability.

- Meeting Consumer Expectations Today’s consumers are more informed and demand transparency and sustainability in packaging. Brands must ensure their packaging choices align with consumer values without compromising product protection or driving up costs. Balancing these competing demands remains a challenge for packaging supply chains.

Future Innovations in the Packaging Supply Chain

- Automation and AI Integration Automation and artificial intelligence (AI) are set to revolutionize the packaging supply chain by improving operational efficiency and reducing human error. Automated processes in packaging production, warehousing, and distribution can significantly reduce lead times and costs. AI-powered systems will enable predictive analytics for demand forecasting, inventory management, and optimizing transportation routes, further enhancing supply chain resilience.

- Blockchain for Enhanced Transparency Blockchain technology offers the potential to create fully transparent packaging supply chains. By using blockchain, companies can track the journey of packaging materials from sourcing to delivery, ensuring authenticity and compliance with sustainability standards. This increased visibility benefits both consumers and regulatory bodies, allowing for greater trust and accountability in the supply chain.

- Advanced Recycling Technologies Future developments in recycling technology will play a key role in closing the loop on packaging materials. Chemical recycling, which breaks down plastics into their molecular components, offers a way to recycle materials that are traditionally difficult to process. As these technologies become more cost-effective and scalable, they will enable higher recycling rates and reduce dependency on virgin materials.

- 3D Printing for Custom Packaging 3D printing is emerging as a disruptive technology in packaging, offering the potential for on-demand, custom packaging solutions. This innovation could significantly reduce material waste, optimize packaging designs, and allow for faster production cycles. As 3D printing technology advances, it could become a staple in localized packaging production, further reducing the environmental impact of transportation.

- Sustainable Packaging Innovations Looking ahead, we can expect continuous advancements in sustainable packaging materials, such as water-soluble films, compostable plastics, and plant-based alternatives. These innovations will further drive the shift away from traditional plastics. The development of more durable and lightweight materials will also improve the efficiency of the packaging supply chain by reducing transportation costs and emissions.

The packaging supply chain is undergoing rapid transformation as sustainability, digitalization, and consumer demands reshape the industry. Despite the challenges posed by rising material costs, supply chain disruptions, and regulatory pressures, companies are investing in innovation to build more resilient and efficient systems. In the coming years, automation, blockchain, and sustainable packaging materials will drive significant changes in how packaging is produced, distributed, and managed. By staying ahead of these trends and adopting innovative solutions, businesses can ensure their packaging supply chains remain competitive, sustainable, and responsive to evolving market demands.

Own your copy of our reach study and stay informed: https://www.towardspackaging.com/price/5066

If you have any questions, please feel free to contact us at sales@towardspackaging.com

About Us

Towards Packaging is a leading global consulting firm specializing in providing comprehensive and strategic research solutions. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations. We stay abreast of the latest industry trends and emerging markets to provide our clients with an unrivalled understanding of their respective sectors. We adhere to rigorous research methodologies, combining primary and secondary research to ensure accuracy and reliability. Our data-driven approach and advanced analytics enable us to unearth actionable insights and make informed recommendations. We are committed to delivering excellence in all our endeavours. Our dedication to quality and continuous improvement has earned us the trust and loyalty of clients worldwide.

Browse our Brand-New Journal:

https://www.towardshealthcare.com

https://www.towardsautomotive.com

For Latest Update Follow Us: https://www.linkedin.com/company/towards-packaging/

Get Our Freshly Printed Chronicle: https://www.packagingwebwire.com/